By digitizing manufacturing execution through MES, we provide a wide range of solutions, including not only standardizing operations and improving productivity for single processes and single factories, but also visualizing production results at multiple global production bases and linking information with equipment (IoT).

Features

B-EN-G has members with experience in implementing systems such as MES and IoT in both the process manufacturing and discrete manufacturing industries. Each member understands the customer's manufacturing processes and on-site issues, and based on the customer's needs, they provide down-to-earth solutions that look beyond the ideal to reality.

Related URL: Column series "Key points for implementing MES"

B-EN-G supports the implementation of solutions that strike a balance between standardization and the strengths of each location by deploying standards for manufacturing operations and other business processes as templates to each site.

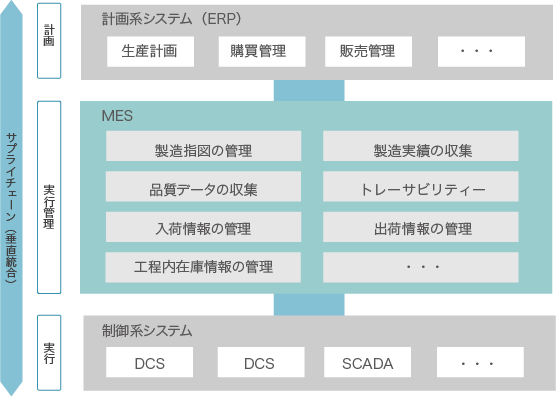

In MES, it is important to link planning/performance information with ERP (Enterprise Resource Planning) as well as with DCS/PLC/SCADA and other control system devices.

B-EN-G has extensive experience in ERP production management, and supports customers based on our extensive knowledge regarding system coordination between MES and ERP.

Related Solutions

DELMIA Apriso

An MES solution provided by Dassault Systèmes (France) that supports manufacturing execution management and supply chains.

PAS-X MES

Manufacturing execution system specialized for the pharmaceutical industry provided by Kerber Pharma (Germany)

BatchLine Lite MES

BatchLine社が提供する医薬品(医療機器)製造業界向けの製造記録電子化のためのクラウドソリューション

AVEVA PI System

A historian solution that collects, stores, and visualizes real-time data from various manufacturing operations

BIOVIA Notebook/BIOVIA Pipeline Pilot

Research information management solution for the process industry provided by Dassault Systèmes (France)

IoT

Supporting the promotion of smart factories by leveraging IoT collaboration technology and product groups to solve shop-floor challenges in the manufacturing industry

SAP EWM

Supports vertical integration of information through the warehouse management system SAP EWM, which links everything from ERP to the automated warehouse PLC

Case Study

Ask the Professionals

Useful Resources