Features of B-EN-G's SAP Business

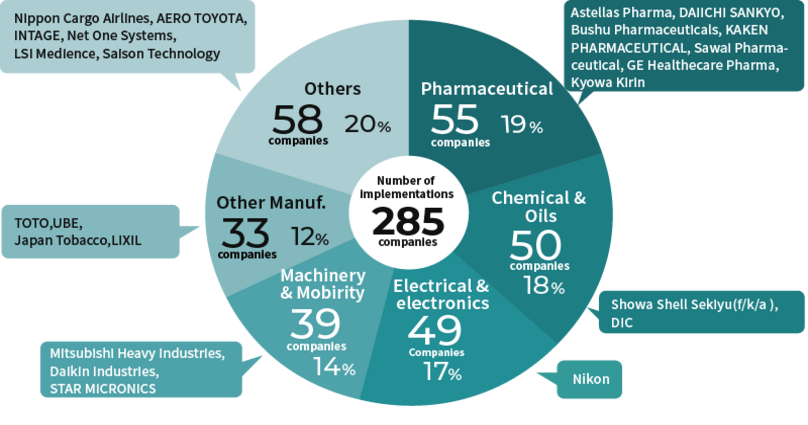

B-EN-G became Japan's first SAP partner in 1991, and implemented SAP for the first domestic user in 1993. We believe that the strength of the SAP product group lies in its comprehensive strength, which is achieved by combining comprehensive peripheral solutions with ERP at its core.

B-EN-G has built up a track record of implementing SAP products in nearly 300 companies, primarily in the manufacturing industry, as the optimal solution for resolving the problems of many customers.

In addition to our extensive knowledge of manufacturing operations and systems, we are actively involved in the latest technologies, including AI, and strive to solve our customers' problems.

We provide a wide range of solutions to the challenges facing the manufacturing industry, from management to on-site operations.

Our company has extensive knowledge of ERP in the manufacturing industry and has the advantage of being able to oversee the entire corporate system.

We provide comprehensive solutions to issues in a variety of related business areas, focusing on ERP.

We will optimize your business processes and utilize each data to truly strengthen your competitiveness.

Examples of themes that B-EN-G has handled

Consultants with extensive knowledge of manufacturing business processes and data have systematized their experience

We guide your projects to success through our methods.

Abundant talent and proven track record

- More than half of the members are in charge of logistics areas such as manufacturing and purchasing

- Related URL: Ask a Professional

- 80% manufacturing

- Related URL: Latest SAP Awards and past awards

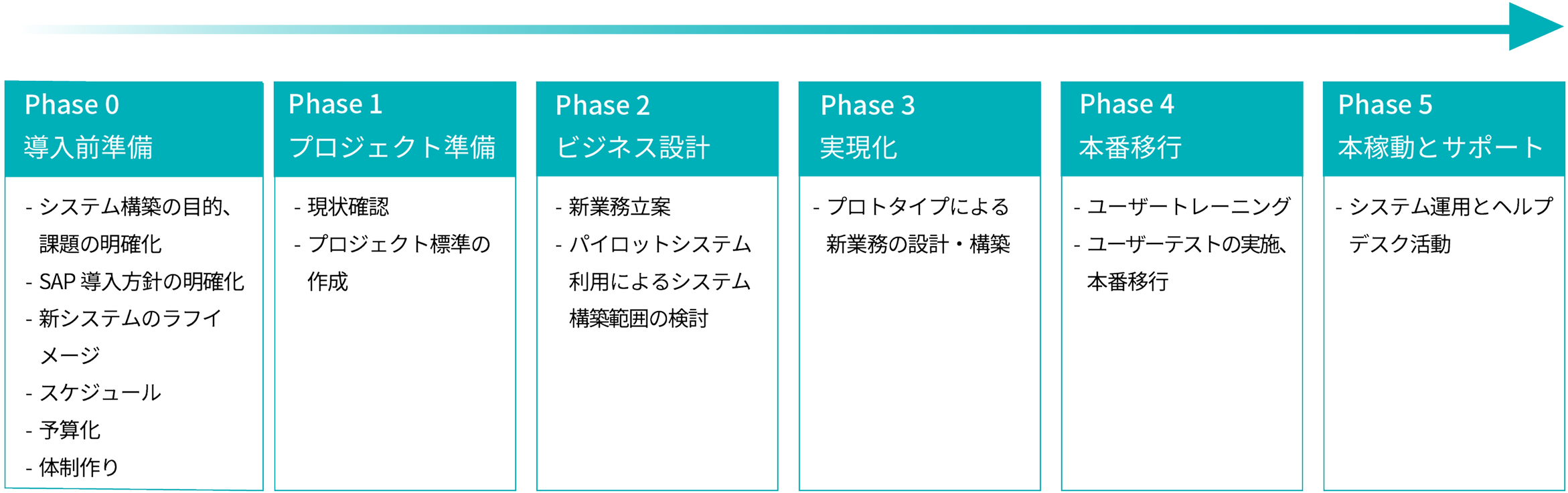

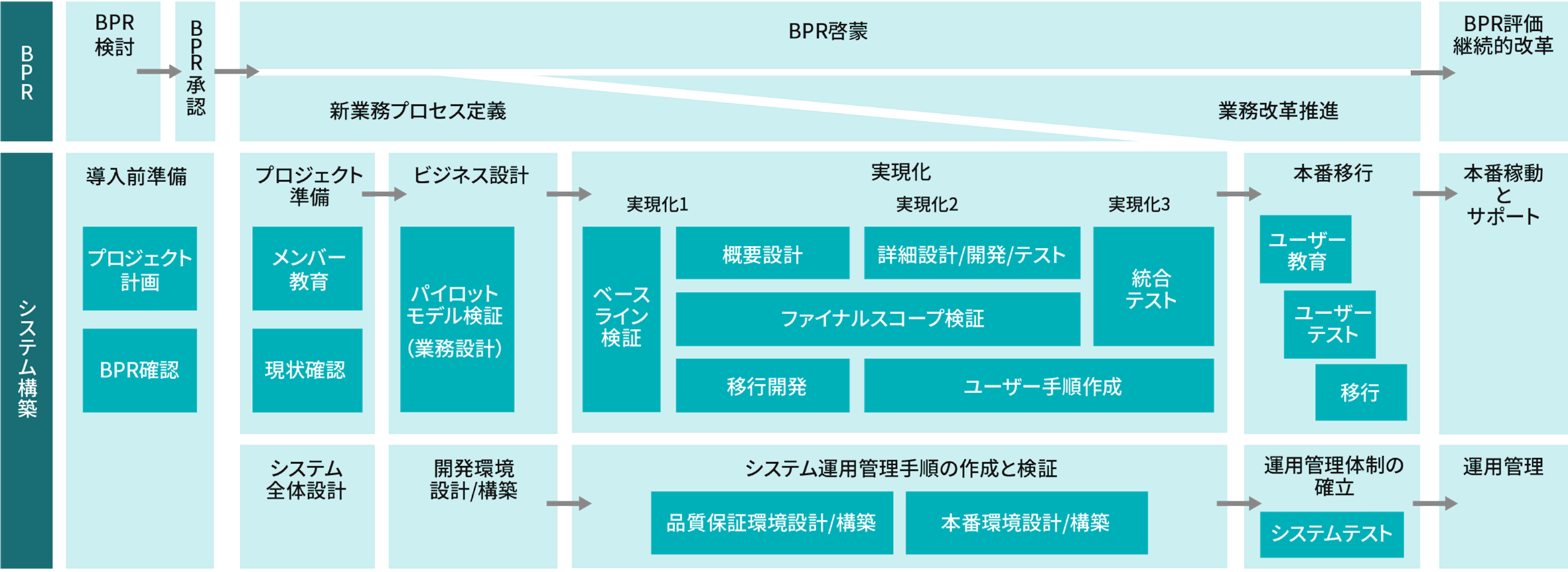

Methods

Our "high quality" is supported by our unique implementation methodology, "TOPPLAN-SAP." By dividing the construction process into five stages and building prototypes in each phase while gradually refining the system, we are able to reliably create an SAP system that is optimized for your business.

Unique implementation methodology "TOPPLAN-SAP"

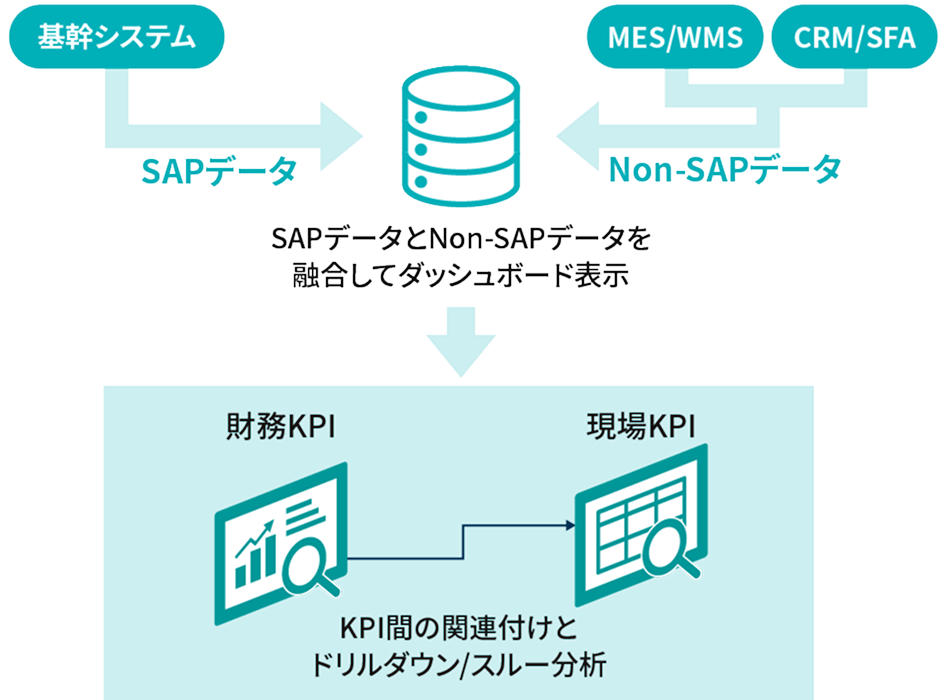

We support the realization of data-driven management through our knowledge of manufacturing and ERP.

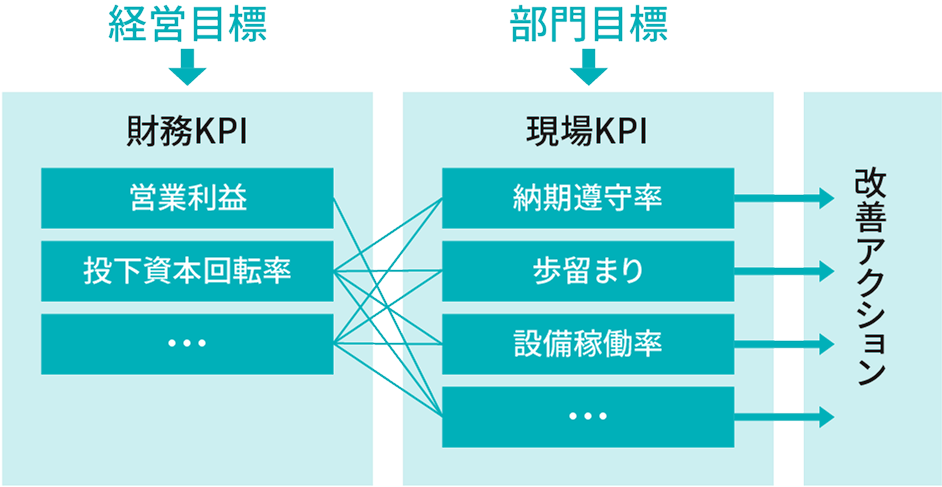

An example of data utilization that organically connects manufacturing site data and ERP data

Link financial KPIs with operational KPIs to guide on-site improvement actions aimed at improving business goals. Visualize on-site activities and management activities, and clarify action plans for improvements.

To achieve this, data from SAP sources and non-SAP source systems such as Salesforce (CRM) and Apriso (MES) are collected into an integrated platform. By drilling down and through between KPIs using the SAP data platform, problems can be analyzed and appropriate actions can be taken.

We propose system improvement plans based on operation and maintenance support.

We will propose system utilization promotion/improvement plans based on the system utilization and issues identified through operation and maintenance support, as well as our own know-how.

We also support conversion (upgrade) from ECC6.0 to SAP S/4HANA.

Related page: SAP S/4HANA Migration Page

We are constantly working on new technologies and solutions that are needed "now"

We keep up with the latest SAP solutions to keep up with the ever-changing technological trends, supporting business reforms for companies, particularly those in the manufacturing industry.

Current Initiatives

SAP Business AI

SAP Business AI utilization support

SAP Joule (Co-Pilot function) supports the use of AI functions built into SAP S/4HANA, and has begun supporting the development of custom AI functions using the SAP AI platform.

Related URL: Column "How to get started with SAP's AI 'Joule'"

SAP Signavio

Process visualization and business improvement support

Using Signavio, the company will begin supporting the creation of a continuous improvement cycle by visualizing complex manufacturing processes based on data.

Related URL: Column "Visualizing business processes and continuous process improvement with SAP Signavio"

SAP SAC BI/Datasphere

KPI management support

Clarifying the relationship between financial KPIs and field KPIs, and supporting data standardization and centralized management through SAP Datasphere and SAC (SAP Analytics Cloud) BI

Related material: Lecture abstract: "KPI setting and analysis architecture to maximize the use of data from SAP S/4HANA and on-site systems"

SAP SAC Planning

Support for implementing budget management solutions using SAC Planning

Supports the improvement of accuracy of budget planning using AI. Supports the elimination of personal dependency by systematizing work. Implementation templates will be provided in the future.

Related URL: Column "Utilizing SAC's AI Functions - Future Budget Management Integrating Planning, Forecasting, and Analysis"

SAP EWM

Support for collaboration between ERP and automated warehouse equipment

Optimize by utilizing the linkage function between SAP EWM and automated warehouses. Support the realization of a vertically integrated system linking ERP to the automated warehouse PLC.

SAP extension development methodology

Using the Developer extension

In-App Development Support

Supporting the implementation of extensions tightly coupled with objects within SAP S/4HANA to achieve a clean core that allows for continued utilization of the latest ERP technologies

Related URL: Column "Extended Development to Maintain a Clean Core - Developer Extension"

See more

1991

Supporting the first domestic project as Japan's first SAP partner

In 1991, we signed the first partnership agreement in Japan with SAP. In 1993, we supported the implementation of the system for the first domestic user (a pharmaceutical manufacturing and sales company).

2004

First introduction in Japan

Supporting the introduction of Ariba on-premise version to the first domestic user (pharmaceutical manufacturing and sales company)

2006

Introduction as a leader in SOA

We quickly established an SOA Competence Center, conducted technical verification and operation in collaboration with global leading companies, and published the evaluation results.

2013

Leading the way in launching implementation support services

Started providing implementation support services immediately after the release of the predecessor solution (SAP S&OP)

2013

First cloud version introduced in Japan

Supporting the introduction of the Ariba cloud version to the first domestic user (pharmaceutical manufacturing and sales industry) *Corresponding to the current SAP Business Network

2014

Launch of the system/management consolidation template

Providing templates incorporating knowledge of implementing legal consolidation and management consolidation in SAP BPC

2019

First introduction in Japan

We were one of the first to adopt the Public Cloud Edition of SAP S/4HANA, a cloud version of which had hardly been adopted by Japanese companies, and introduced it to our global manufacturing bases.

2020

First introduction in Japan

Supported the implementation of Japan's first "RISE with SAP" project and won the "Project Award Excellence Award" at the "SAP AWARD OF EXCELLENCE 2023"

2014

Started support for SAP BTP platform expansion development

Supporting the development of interface functions between existing systems and SAP S/4HANA in conjunction with the introduction of SAP IBP

Related Solutions

Case Study

Daiichi Kigenso Chemical Industry Co., Ltd.

Integrate and standardize global operations and systems with a Fit to Standard approach

Bushu Pharmaceuticals Ltd.

Renewing core business systems with "SAP S/4HANA" to further improve corporate value

Nippon Cargo Airlines Co., Ltd.

Aiming to Shift to High-Value-Added Businesses: A Case Study of Accounting System Restructuring with RISE with SAP