Production Scheduler Integrated with SAP S/4HANASAP Production Planning and Detailed Scheduling

SAP Production Planning and Detailed Scheduling (PP/DS) creates detailed production schedule plans and work sequence plans. Seamless and real-time data linkage by being included in SAP S/4HANA® makes production planning operations more efficient and sophisticated.

Overview

We can develop unconstrained production schedule plans, as well as those that take into account hourly production capacity constraints and material constraints.

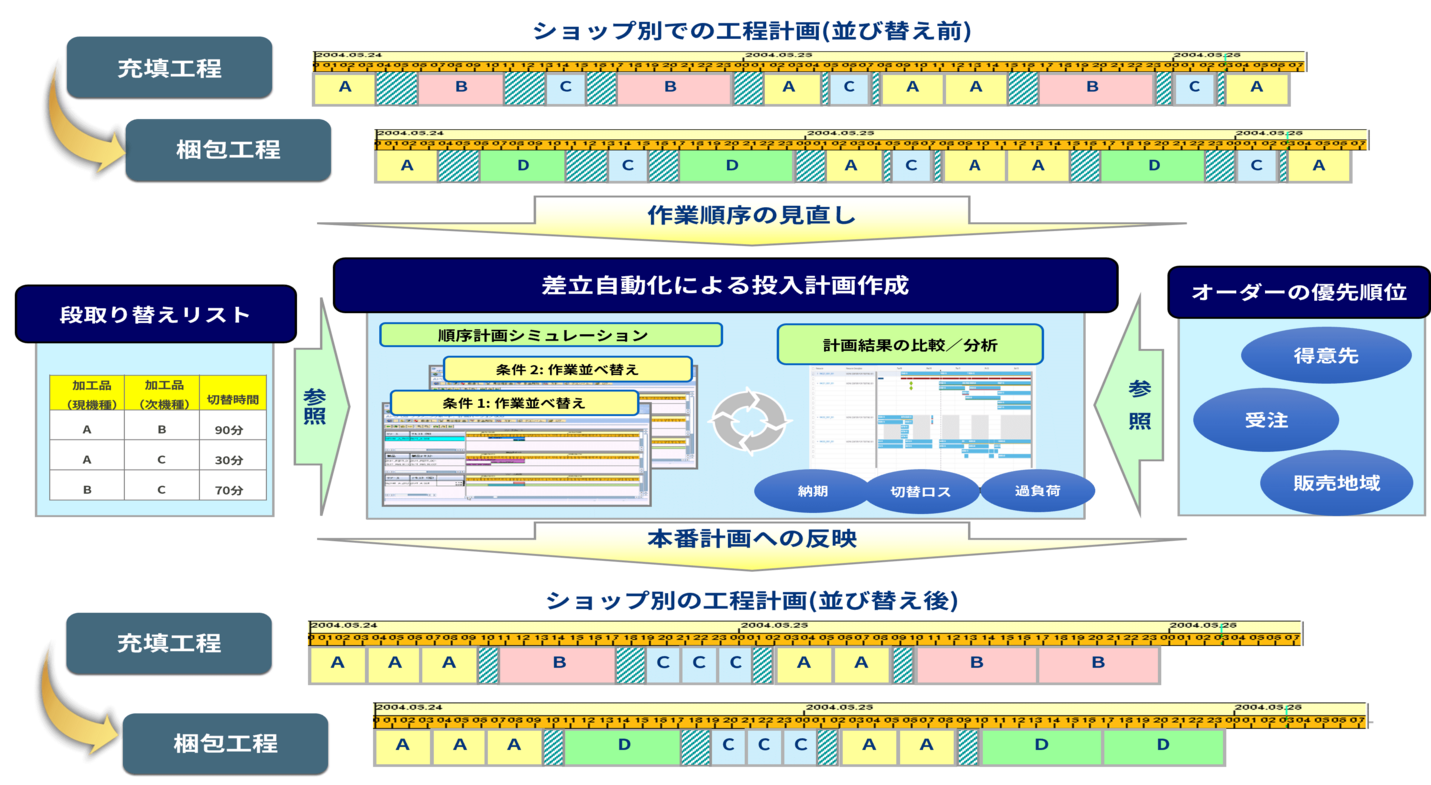

Work sequencing plans are developed taking into account order priority and production line set-up changes.

In order to take into account product characteristics and other factors, the plan execution is divided into steps, and the planning logic can be changed for each step to enable planning in a single execution.

Since it is embedded in SAP S/4HANA, master data integration and master data maintenance can be simplified, and because it is integrated in transaction data as well, execution and planning operations can be seamlessly linked to achieve greater operational efficiency and sophistication.

Features

1) Production schedule planning

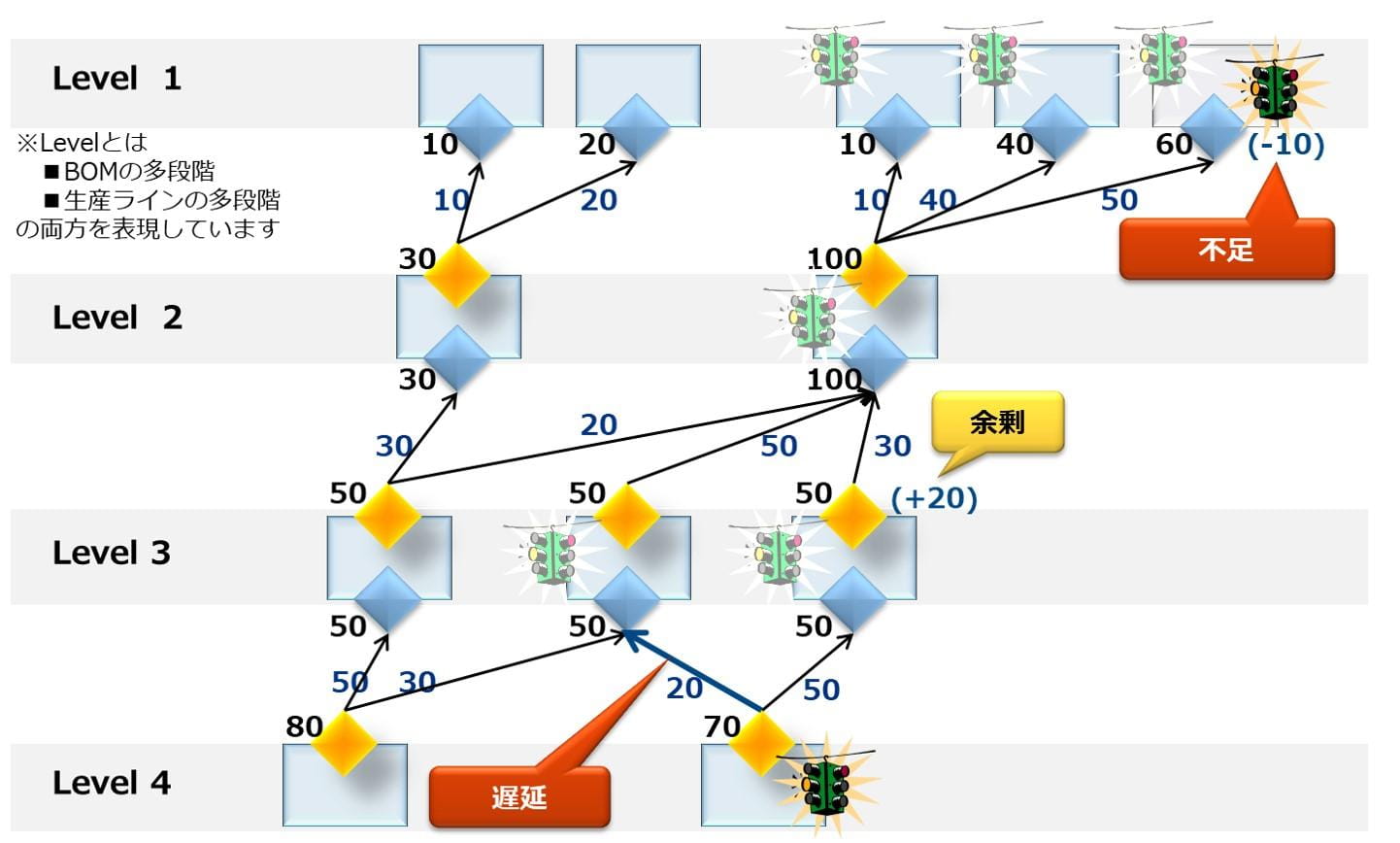

- Product production planning + parts procurement planning at multiple locations (multi-level) and BOM development (multi-level)

- Appropriate resource adjustment (alternative resource allocation, etc.)

- Compatible with various production formats: MTS (make-to-stock), MTO (make-to-order), etc.

- Order pegging: dynamic/fixed/manual

- Alert monitoring

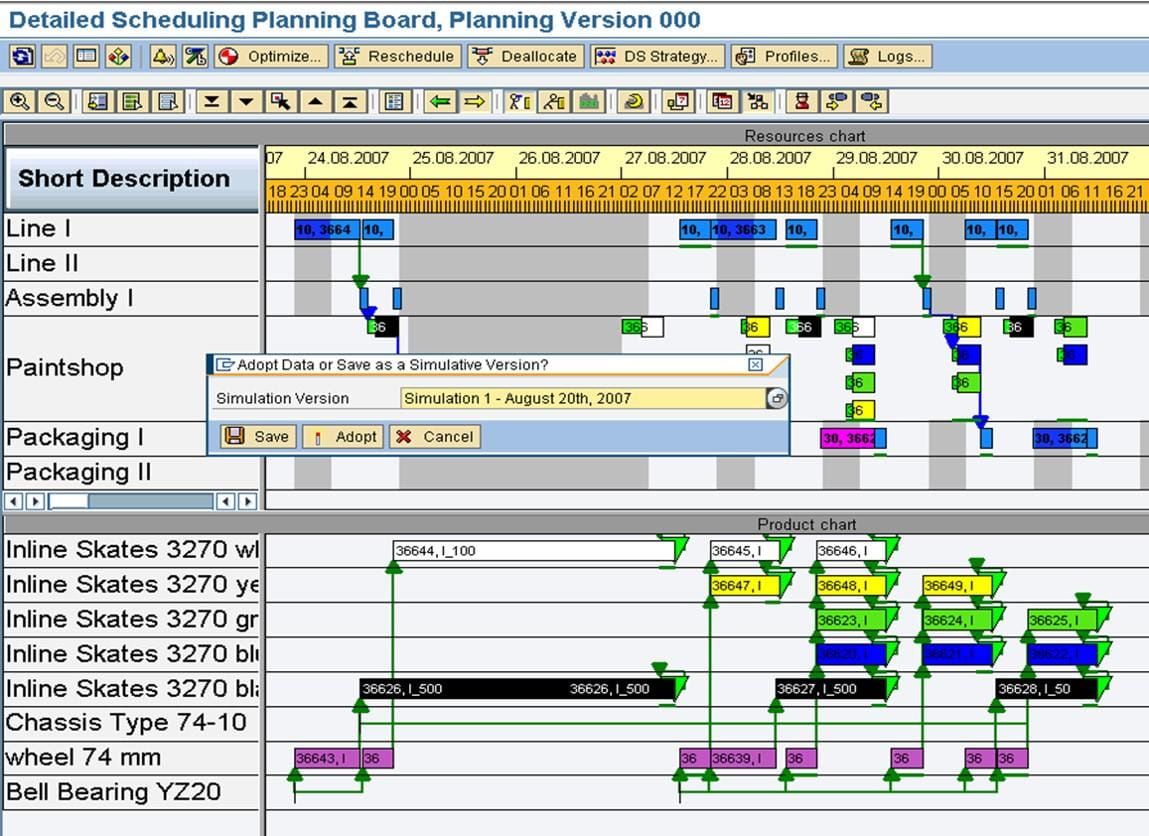

2) Work order planning

- Optimizer (detailed schedule optimization, order optimization)

- Manual planning and adjustment using Gantt charts

- Top-down, bottom-up planning

- Alert monitoring

3) Integrated management of master data/transaction data

- Use common master data between SAP S/4HANA and PP/DS (items, resources, routing)

- Seamlessly link transaction data in real time with SAP S/4HANA and PP/DS

Benefits

- Improved delivery rate due to improved planning accuracy

Executable production schedule planning that takes into account production capacity constraints and parts/material constraints leads to improved planning accuracy, and based on this highly accurate plan, execution accuracy also improves, contributing to meeting deadlines.

- Cost minimization by optimizer (optimization planning engine)

Equipped with a planning engine that minimizes total costs such as setup costs, delay costs, and manufacturing costs, making it possible to plan production schedules with manufacturing-related costs in mind.

- Minimize the impact by quickly detecting anomalies (fluctuations)

Increase visibility of the entire supply chain, whether between departments or inside or outside the company. Reduce risks by planning ahead for future risks such as profit losses due to currency fluctuations or supply capacity shortages due to sales increases.

- Take prompt and appropriate action by confirming the impact of abnormalities (fluctuations)

All related objects in inventory, production plans (planned orders, manufacturing orders), and procurement plans (purchase requisitions, purchase orders) can be linked (pegged) from demand (demand plans, sales orders) to inventory, production plans (planned orders, manufacturing orders), and can be checked from upstream to downstream processes. No matter where an alert occurs, the impact can be tracked on a document-by-slip basis, allowing you to quickly take appropriate action.

- Reducing IF development costs and master management costs through seamless data linkage

Seamless, real-time coordination of master data and transaction data with the core system (SAP S/4HANA) reduces interface development costs related to data coordination, and reduces management costs such as dual management of master data.

- Improving the efficiency of production planning operations and reducing lead time

By automating feasible plans that take constraints into account and automatically executing planning logic tailored to product characteristics, the lead time for production planning operations can be reduced and made more efficient, enabling a shift to "high value-added operations" that should be devoted to more time.

B-EN-G Consulting Services

Based on our deep understanding of the manufacturing industry's on-site operations, from procurement to production, logistics, sales, and support, and our extensive experience as an SIer, including introducing Japan's first ERP system for the manufacturing industry, we We provide consistent support from SCM concept to system implementation and support for continuous improvement activities beyond that.