Daiichi Kigenso Kagaku Kogyo, the world's leading manufacturer of zirconium compounds, has launched a project called "D-Value" to integrate and standardize the systems and business processes of its global bases, and has adopted "SAP S/4HANA® Cloud" as the system for this purpose.

The company overcame the disruption caused by the COVID-19 pandemic and completed the implementation. It has established a management foundation that allows it to quickly grasp the situation of the entire group. Currently, it is working to continuously maintain and improve processes, and to utilize data with cutting-edge technologies such as AI.

*The company received the "SAP Japan Customer Award 2024" as an example of business transformation.

Issues before implementation

- As the automotive industry, a major customer, enters a period of major transformation, there is an increasing need to establish a digital transformation platform that will serve as the foundation for business reforms to adapt to changes in the business environment.

- At the head office, sales plans, production plans, and actual cost calculations were managed using separate systems, and the core system was used only for collecting actual results, which was a very limited purpose.

- Because each overseas base had its own system, it was difficult for headquarters to see the situation until the financial statements were submitted.

Implementation Results

- By unifying the business processes, systems, and code systems of all global bases, the flow of goods and money across the entire group has become visible, contributing to the speed of management decisions.

- Sales plans and production plans are linked within the system, automating delivery date responses and reducing labor.

- We have built a system infrastructure that allows us to grasp production, sales, and inventory results in real time.

- By automatically linking order data between groups, manual input work is reduced and the risk of work errors is reduced.

- By implementing actual cost calculation within SAP S/4HANA Cloud, interfaces have been reduced and the system configuration has been simplified. Furthermore, more advanced analysis is now possible through financial reconciliation.

Implementation Points

- A Fit to Standard approach minimizes customization and promotes short-term, cost-saving implementation

- After experiencing the new functions of the public version of SAP S/4HANA Cloud, we will build an integrated system that includes manufacturing operations using the private version.

- Achieving stable operation and implementation as planned through close collaboration with partner companies who take on the challenge together

Implemented Products/Solutions

SAP S/4HANA Cloud(Public Edition/Private Edition)

Background of introduction

Building the foundation for a "100-year company" that can respond to changes in the automotive industry, its main customer

Daiichi Kigenso Kagaku Kogyo is a materials manufacturer engaged in the manufacturing, sales, and research and development of inorganic compounds, primarily zirconium compounds, including cesium compounds and rare earth compounds. Zirconium is a rare element with many excellent properties. When converted into compounds, it exhibits a variety of characteristics, including heat resistance and high durability. Utilizing these properties, the company's products are used in various forms throughout society, from industrial fields to household products. Many of the company's products are used in the automotive field, and in 2020, the company was recognized by the Ministry of Economy, Trade and Industry as one of the "Top 100 Global Niche Companies" for its global market share of approximately 40% (company estimate) in the field of automotive exhaust purification catalyst materials.

In 2012, the company established Vietnam Rare Elements Chemical Joint Stock Company (hereinafter referred to as the "Vietnamese subsidiary") as a base for procuring zirconium ore and manufacturing intermediates that are used as raw materials for products.

This has enabled us to establish the world's only "integrated production system within the group," in which intermediates are manufactured from raw ore in Vietnam, and then processed and manufactured in Japan according to customer requests.

D-Value Project Japan Development Leader

Mr. Yoshihisa Hamakami

Regarding the advantages of this system, Hamakami Yoshihisa of the Business Headquarters SCM Center explains, "By locating our headquarters and R&D base in Japan, and our manufacturing bases in both Japan and Vietnam, we have secured our own raw material procurement routes and have a dual supply chain, ensuring a stable supply of products. In the field of zirconium compounds, raw material procurement has traditionally been dependent on China, but in recent years, the geopolitical risks involved have been increasing. Our ability to achieve a stable supply of products while avoiding these risks is a major strength of ours, and is something that is highly valued by our customers."

Meanwhile, the market for zirconium compounds is at a major turning point, with the shift to electric vehicles (EVs) progressing in the automotive industry, which is the company's main customer. In this environment, the company has set a vision of "Becoming a 100-year company together with rare elements," and in anticipation of further growth, launched its 10-year medium-term management plan, "DK-One Next," in 2022.

"DK-One Next" has set six pillars for efforts to continue creating new businesses while overcoming environmental changes that are likely to occur over the next 10 years: "creating new businesses," "reforming revenue structure," "realizing innovative manufacturing," "practicing organizational development that continues to produce results," "further fostering Kigenso's unique identity," and "sustainability initiatives." As a measure to build a digital transformation (DX) foundation that will support the realization of these goals, the company has been promoting "D-Value," a business and system transformation project using "SAP S/4HANA Cloud."

Project Background

Fit to Standard to shorten implementation time and reduce costs

Regarding the reason for adopting SAP S/4HANA Cloud for the D-Value project, Rie Mitsui of the ICT Department of the Corporate Management Headquarters explains as follows:

D-Value Project Overall Promotion Leader

Rie Mitsui

"Rather than simply upgrading the system, we wanted to create a simple configuration that maximizes the use of the standard functions of SAP products, which can be described as a 'treasure trove,' and we wanted to review our business processes and incorporate new ways of thinking without being bound by the rigid scope of use."

This is what is known as Fit to Standard. The reason behind this is that the company believed that its core business processes could not be a source of differentiation in themselves.

"We thought that adopting a 'clean core strategy' that eliminates individual company processes and personal processes as much as possible and avoids customizing the system would not only optimize the data stored in the system, but would also shorten project periods and reduce costs," says Mitsui.

Based on this policy, the company decided to introduce the public version of SAP S/4HANA Cloud to its overseas sales companies.

The private version was adopted for the Vietnamese subsidiary and head office after comprehensively considering factors such as the implementation project schedule, the public version's compatibility with Vietnamese requirements, and its flexibility for manufacturing bases. However, Mitsui continued to explore the possibility of introducing the public version of SAP S/4HANA Cloud to the Vietnamese subsidiary and head office until the very end in order to thoroughly implement the "Fit to Standard" and "Clean Core" strategies.

Building a system that links procurement to sales to advance global SCM

When rolling out D-Value to the head office, the company set the goal of "improving SCM across the entire group," and Hamakami took on the role of project leader.

Regarding this goal, Hamakami said, "It means globally optimizing business processes, from raw material procurement to sales, and building a digital transformation foundation to realize the six pillars of DK-One Next. For example, one of the pillars is 'reform of revenue structure,' and to achieve this, it is necessary to reduce inventory as much as possible and maintain good cash flow. To do this, it is important to firmly link sales and production plans with data as the core, and to run operations so that 'production volume' and 'sales volume' are as close to equal as possible. We used SAP S/4HANA Cloud to create a system for this purpose."

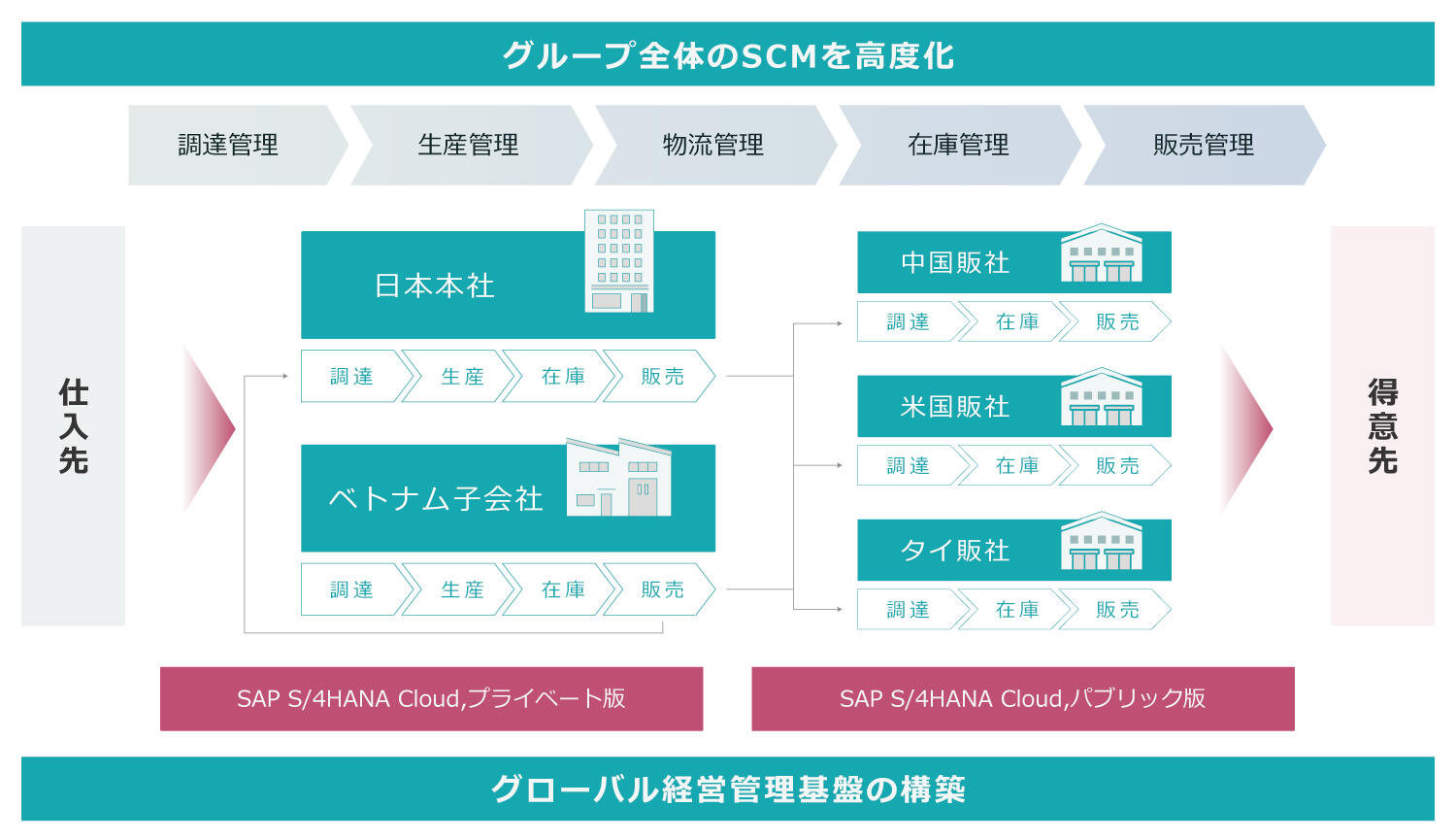

Globally optimize business processes from raw material procurement to sales, and build a digital transformation foundation to realize the six pillars of DK-One Next.*Figure created by B-EN-G based on interviews.

Specifically, by linking sales budgets, sales plans, and production plans and managing future inventory in the system, a system that automatically proposes delivery dates was realized using the standard functions of SAP S/4HANA Cloud.In addition, customer master and item master data were organized globally to review and unify the code system, and orders and deliveries between groups were linked between systems.Furthermore, actual cost calculations can now be performed within SAP S/4HANA Cloud, simplifying the system configuration.

Implementation Results

Real-time visibility into business performance and future plans

Hamakami says, "The best thing about promoting this D-Value project is that we can now monitor business results and future plans in real time. I expect this will definitely speed up management decisions."

Mitsui is enthusiastic, saying, "It is of great significance that we are now able to grasp the situation and plans of the entire group through data, and I feel that we have laid the foundation for DX to realize data-driven management. Going forward, I would like to contribute to strengthening group management by considering and verifying from various perspectives how we should analyze and utilize the performance data and planning data managed by the system."

Another achievement that Mitsui cited as a result of the D-Value project was that the implementation of SAP S/4HANA Cloud at each location, including the head office, proceeded as planned and continues to operate stably. Mitsui and Hamakami cited their choice of B-EN-G as their project partner as the biggest factor in this success.

"B-EN-G always worked closely with our company to understand its challenges and asked, 'How can we make this happen?' as they advanced the project. I strongly felt that 'The key to success in implementing an ERP system is who you work with.'"

The company is also considering using AI to make effective use of the data that will be accumulated in the system, and is counting on the generous support of B-EN-G to help it make effective use of such innovative technology.

Case study company introduction

| Company Name | Daiichi Kigenso Chemical Industry Co., Ltd. |

| Establishment | May 21, 1956 |

| Head office location | Kitahama, Chuo Ward, Osaka City, Osaka Prefecture |

| Business Activities | Manufacturing, sales, and research and development of inorganic compounds such as zirconium compounds, cesium compounds, and rare earth compounds |

| Overseas bases | Manufacturing and sales base: Vietnam Sales bases: China, Thailand, USA |

| Company website | https://www.dkkk.co.jp/ |

*Please note that organization names, positions, numerical data, etc. in the article are based on the time of the interview and may have changed by current viewing.

If you would like to know more about this case study, which won the "SAP Japan Customer Award 2024," please download the case study below.

Related Solutions

Relevant information and case studies based on solutions presented above.

Related Case Studies

Nippon Cargo Airlines Co., Ltd.

Aiming to Shift to High-Value-Added Businesses: A Case Study of Accounting System Restructuring with RISE with SAP

Logistics

ERP

SAP

Nxera Pharma Japan Co., Ltd. (Formerly Idorsia Pharmaceuticals Japan Ltd.)

Compatible with Global Requirements: Case Study of a Project to Build a Sales Management System Compatible with JD-NET

Medicine

ERP

Pharmaceutical & Medical Device Industries

SAP

GE Healthecare Pharma Limited

Promoting Understanding among Global IT Teams: JD-NET-compliant Enterprise Resource Planning System Implementation Project Case Study

Medicine

ERP

Pharmaceutical & Medical Device Industries

SAP