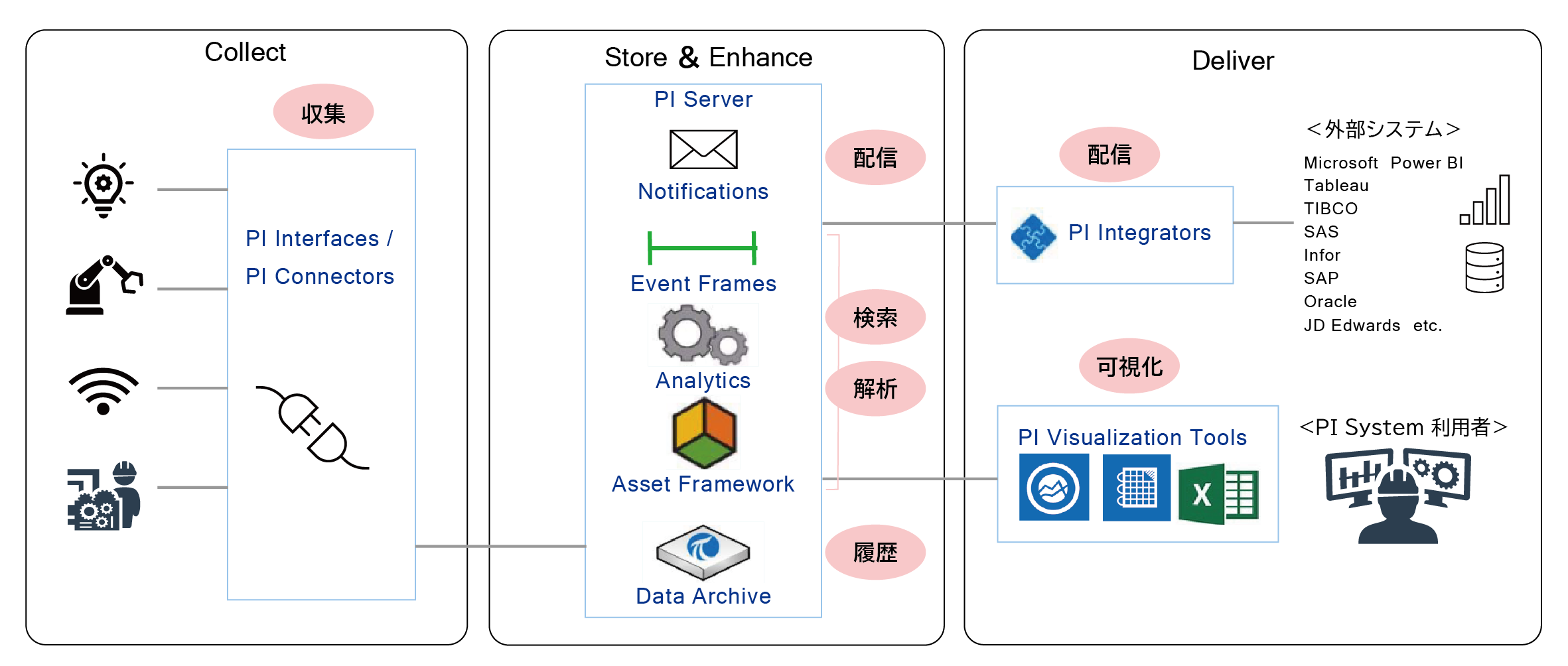

Promoting digital transformation at manufacturing sites by collecting, storing, and visualizing data from equipment and sensor devicesAVEVAPI System

The AVEVA ™ PI System ™ is a historian solution that accelerates digital transformation (DX) in the manufacturing industry by collecting, storing, and visualizing real-time data from various manufacturing operations, enabling data-driven decision-making aimed at business resilience (the ability to flexibly respond to and overcome difficult risks) and sustainability.

Overview

The AVEVA PI System accumulates real-time data from equipment and sensor devices. This accumulated data is visualized for easy use and can be analyzed from every angle to optimize the efficiency of equipment operations at manufacturing sites.

function

- PI Interfaces/PI Connectors

-

- Factory-wide (hundreds of thousands of data points), high-speed (seconds to minutes) data collection

- Importing text files in various formats can be handled with simple scripts.

- Standard interfaces with industry-standard devices and measurement and control devices (over 450 types)

Standards: OPC-UA, OPC-DA, BACnet, etc.

DCS: Yokogawa Electric, Hitachi, Toshiba, azbil, Fuji Electric, etc.

PLC: MELSEC, SYSMAC, MICREX, etc.

SCADA: iFIX, InTouch, Siemens, Rockwell, etc.

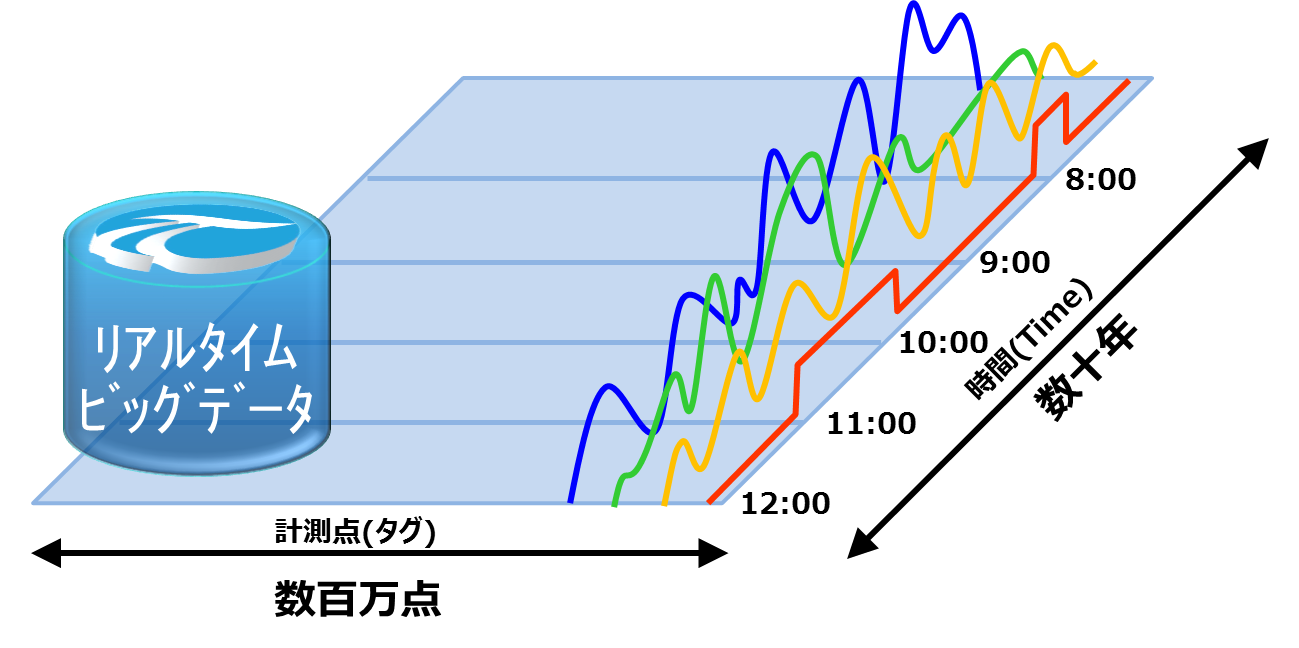

- PI Data Archive

-

The core functionality of the PI System. Time series database

- High accuracy: No averaging, just store and use the collected real-time data in its original form

- Large volume: All measuring points managed by one system

- Long-term: Real-time historical data is stored and available online for a long period of time

- PI Asset Framework

-

Another core function of the PI System. It is a platform for structuring and managing accumulated data, and acts as a bridge between the Data Archive and the PI Visualization Tools.

- Accumulated time series data (event data) and static data (RDB) can be organized, hierarchized, linked (batch trend), analyzed, and monitored with alerts.

- Alert notifications can also be sent based on thresholds and decision logic defined within the PI System.

- PI Integrators

-

- By utilizing the API and SDK provided by the PI System, it is possible to link with external systems such as SAP S/4HANA and MES.

- PI Visualization Tools

-

- PI Vision

A web browser-based tool for analyzing and visualizing accumulated data

- Intuitive operation allows for easy screen creation by anyone, anytime

・Monitor real-time data with a graphical UI

- Allows users to utilize data themselves and discover new things - PI Data Link

Microsoft Excel add-on tool

- Intuitive operation allows for easy screen creation by anyone, anytime

・Accumulated data can be downloaded/uploaded

・By combining with standard Excel functions, it can be used as a data analysis tool, report, etc.

- PI Vision

Features

- Collects a wide variety of equipment data from over 450 different interfaces, and efficiently stores huge amounts of time-series data for the long term using proprietary compression technology

Real-time data collection and long-term storage

- Scattered data can be centrally managed and easily analyzed and visualized on a web browser using tools such as PI Vision, enabling real-time situational awareness and decision-making.

Centralized data management and visualization

- Easily connects with other data analysis tools, MES, ERP, etc., promoting data utilization in a wide range of fields, including predictive maintenance, quality control, and productivity improvement.

Data integration and utilization

- Equipped with high availability (HA) functionality, it enables expansion without system downtime. It provides highly reliable data from the field to the management level, and supports company-wide business reform.

High reliability and scalability

Benefits

The introduction of the AVEVA PI System goes beyond simply collecting data; by utilizing it effectively, it will bring about transformation across the entire production operation.

- Combining real-time data with advanced analytics improves process efficiency, optimizes production data, and enables sustainable operations

Accelerated decision making and operational optimization

- Predictive maintenance reduces unplanned downtime and optimizes maintenance costs

Reduce costs and increase productivity

- Reduce time spent on data management by eliminating differences in how data is collected, enriched, stored and visualized across sites and standardizing the underlying data architecture, dashboards and reports

Standardization and centralization of data utilization

- For example, in the pharmaceutical industry, the PI System has helped many companies address GxP regulatory requirements and enabled efficient digital laboratory platforms, helping companies reduce their environmental impact while also increasing compliance with strict industry regulations.

Strengthening compliance

B-EN-G implementation support

As AVEVA's Technology Partner, B-EN-G will provide comprehensive support for the implementation of the AVEVA PI System, which will promote digital transformation in customers' manufacturing sites.

- We handle a wide range of solutions from ISA-95 Level 2 to Level 4, and support comprehensive system implementation, including data integration with peripheral systems (ERP, MES, etc.).

Comprehensive data integration based on ISA-95 and enhanced MES integration

- We have a wealth of experience in implementing various solutions for pharmaceutical industry customers. When implementing the AVEVA PI System, we will meet various regulatory requirements and ensure transparency and data integrity of the manufacturing process. Based on the principles of Quality by Design (QbD), we will support the implementation of a system that helps in continuous monitoring and analysis of Critical Quality Attributes (CQA) and Critical Process Parameters (CPP).

Extensive experience in the pharmaceutical industry and support for CSV/GxP compliance

- Using structured data from the AVEVA PI System, various KPIs are visualized in real time. By drilling down into those KPIs, it supports quick decision-making at manufacturing sites and also supports sustainability activities such as reducing CO2 emissions by linking data with other systems.

Real-time visualization and drill-down of KPIs for faster decision making

Related Solutions

Computerized System Validation (CSV) support service

Support services for system assessment, development work, maintenance of operational procedures, and verification work for companies entering the pharmaceutical manufacturing industry and medical device field.

PAS-X Manufacturing Execution System for the Pharmaceutical Industry

A manufacturing execution system that covers all major lifecycle stages of pharmaceutical and biopharmaceutical manufacturing, from process development to product manufacturing and packaging.

Manufacturing and Logistics Execution Management Solution DELMIA Apriso

Dassault Systèmes' DELMIA Apriso is a manufacturing and logistics execution management system that supports global supply chains, including not only domestic but also overseas bases.