Speaker: Business Engineering Corporation

Solutions Business Headquarters

Digital Business Headquarters Digital Consulting Department

consultant

Fumiya Nakao

Nakao Fumiya's wish to "increase his own unique value" was fulfilled when he was assigned to Japan's first SAP IBP implementation project after joining the company as a new graduate.

Since then, he has been consistently involved in building and supporting the operation of supply chain planning systems. In particular, in projects with consumer goods manufacturers, he has not only implemented systems, but has also worked deeply into the entire supply chain to solve problems, from demand forecasting to inventory optimization and material procurement. At the heart of this is his strong belief that "we should work closely with our customers and not give up until the very end."

The first SAP IBP implementation project in Japan in pursuit of rare value

Participated in

Nakao, who joined Business Engineering (hereafter referred to as B-EN-G) in 2017 after graduating from graduate school, had a clear plan for his career development from the start. "I wanted to increase my own unique value, so I asked the company to assign me to a field where there were not many pioneers," says Nakao.

His wish came true when Nakao was assigned to a department that handled supply chain planning solutions and was assigned to a project for a major medical device manufacturer, where he was responsible for standardizing global S&OP (Sales and Operations Planning) and building a supply chain planning system based on SAP IBP (Integrated Business Planning), the first of its kind in Japan at the time.

"We were fortunate to be able to experience the entire process, from defining business requirements to configuration, system testing, user education and acceptance testing, and operation and maintenance," says Nakao.

Nakao learned an important lesson while working on projects: a project is not complete once the system is installed. It is particularly difficult to solidify requirements from the beginning for planning systems, and it is not uncommon for unexpected problems to arise once the system enters the operational phase.

In fact, this project also faced many unexpected issues after operations began.

"I realized that the mission of B-EN-G consultants is to accompany our clients until they achieve their desired results." (Nakao)

This realization led to a major change in the next project.

Demand forecasting is just the starting point

Synchronize all processes from production to logistics

Nakao, a junior employee in his third year at the company who already has experience with SAP IBP, was newly assigned to a major consumer goods manufacturer to reform S&OP operations and build, operate, and maintain a supply chain planning system. He has now been promoted to PM and is in charge of overall oversight.

What challenges did this consumer goods manufacturer face in the first place?

"Each department created their own plans separately using Excel. The sales department would create a sales plan, and the factory's production management department would then create a production plan, which would then be passed on to the materials procurement department to create a procurement plan. In this way, multiple Excel sheets were relayed to keep the entire company running. This meant that every small change required communication by email or phone, which was a cumbersome process for each department on the ground," says Nakao.

This manual "Excel relay" process was not only time-consuming, but also slowed down business operations. Because planning required time, contact with raw material suppliers was always at the last minute, placing a heavy burden on the suppliers. Furthermore, the consumer goods industry presented unique challenges, with products and plans constantly being renewed to stimulate consumer purchasing desire.

"We needed to create a detailed plan to deal with short product lifecycles, avoid stockouts while ensuring time to modify production equipment for new products, and use up all the materials needed for old products. It was clear that our previous system, which relied on manual Excel relay work, would soon become unsustainable," says Nakao.

The first step was to standardize the demand forecasting that had previously relied on a small number of experienced employees. However, this was only the first step of the project. The next step was to "systematize the entire supply chain," using the forecast data as a starting point to seamlessly synchronize subsequent processes such as production, procurement, and inventory.

"The client had a high-mix, low-volume product strategy, and reducing logistics costs such as inventory storage fees was a top priority. However, simply reducing inventory is not enough. We needed to prevent opportunity losses due to stockouts, while also preventing waste by discarding surplus parts from old products. To resolve this trade-off, we linked demand and supply planning on SAP IBP." (Nakao)

By establishing a system that instantly reflects fluctuations in demand in factory production plans and the amount of materials required, it has become possible to create reasonable production plans and detect inventory risks early.

Furthermore, this chain of information is not limited to within the company.

"Every time there was a change in plans, there was a delay in informing our suppliers, forcing them to make sudden changes. So, we created a system in which all of our suppliers directly use the same IBP system, which is extremely rare in the industry. Suppliers can access the system themselves and check the latest plans, which has enabled us to share information more quickly and respond promptly," says Nakao.

Winning the "trust" of the field through careful end-user service

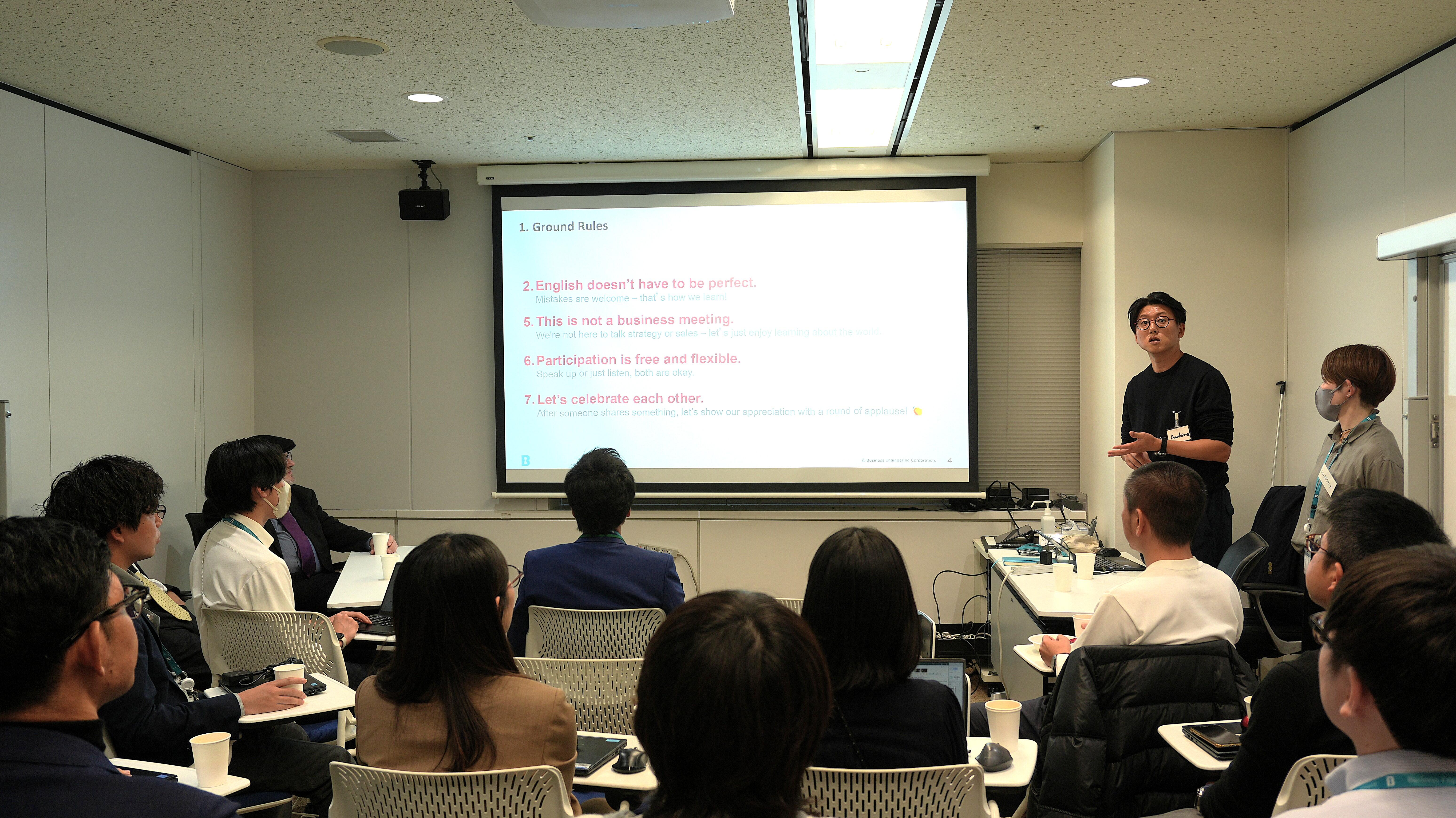

Such ambitious reforms would be meaningless if they were not put to use by end users in the field, so B-EN-G's consulting team focused on maintaining close communication with the workplace.

"After digging deeper and getting feedback not only from the client's PM but also from individual end users, we discovered that there was psychological resistance to changing from the procedures they were familiar with, and dissatisfaction with the system's functionality, revealing that there was room for improvement in many ways," says Nakao.

So, we implemented the following measures:

The first is a response to eliminate vague anxieties that end users have, such as "I don't know how the sales forecast values were calculated, so I somehow can't trust them," or "I want to make production plans based on predictions of future inventory trends, but I'm worried about whether the actual inventory results that form the starting point for the forecasts are being correctly obtained from the core system."

After several months of comparative verification of the system's forecasts and actual results, we were able to gain the understanding and acceptance that "the sales forecasts generated by the system were not significantly different from those generated by the conventional method, and in fact exceeded them."

The second is the detailed response to requests from the field. By quickly responding to detailed requests from end users, such as "We want to prioritize the display of products with high forecast accuracy," "We want to be able to sort by production manager and product type," and "We want to add a simple sheet (listing shipping quantities and dates) to use in discussions and issuing instructions to the logistics department," even going so far as to create individual requirements outside of the standard functions, the system was able to eliminate resistance to the new system.

Another important point is that the company has been working to change the mindset of the entire company by encouraging sales department leaders to set their own business goals, such as setting targets for how much they can shorten the lead time required for planning by using the system's demand forecasts.

The project never ends

Flexible changes in the planning system are needed

Even now that SAP IBP-based planning for the entire supply chain has been firmly established, the project is far from over and continues to evolve.New challenges continue to arise, such as the horizontal expansion of the system to include not only domestic but also overseas bases, the response to peripheral businesses, and the review of planning methods in response to changes in the market environment.

"There is no absolute right way to create a supply chain plan. There are countless individual requirements that depend on people and products, so unifying procedures is an extremely difficult task. At the moment, we are moving forward with projects with the goal of standardizing operations, but on the other hand, completely standardizing procedures could actually make it difficult to carry out operations smoothly. Furthermore, the business issues that companies face are constantly changing. If you overly optimize planning procedures to a certain point in time, you will run into problems such as not being able to respond to new issues that arise. That is the difficulty of planning systems. For this reason, it is very important that the planning system be able to grasp the essence of the issues that customers are facing, work closely with them, and also be able to flexibly respond to change," Nakao says with renewed determination.

The B-EN-G consulting team, led by Nakao, is ready to continue to provide personal support to these consumer goods manufacturers. Nakao himself is also focusing on developing the talent to lead projects after him, and intends to apply the knowledge he has gained in the consumer goods industry to other industries, supporting the operational transformation and business success of various companies.