Next Generation Advanced Planning SolutionLOGIS Production Planner

LOGIS Production Planner (LPP) is a next-generation advanced planning and scheduling solution that can further enhance business effectiveness and competitive advantage in environments where complex planning * is required.

*Complex planning means that there are many equipment constraints and manufacturing rules, and that the way the plan is constructed depends on the experience of the planner.

Overview

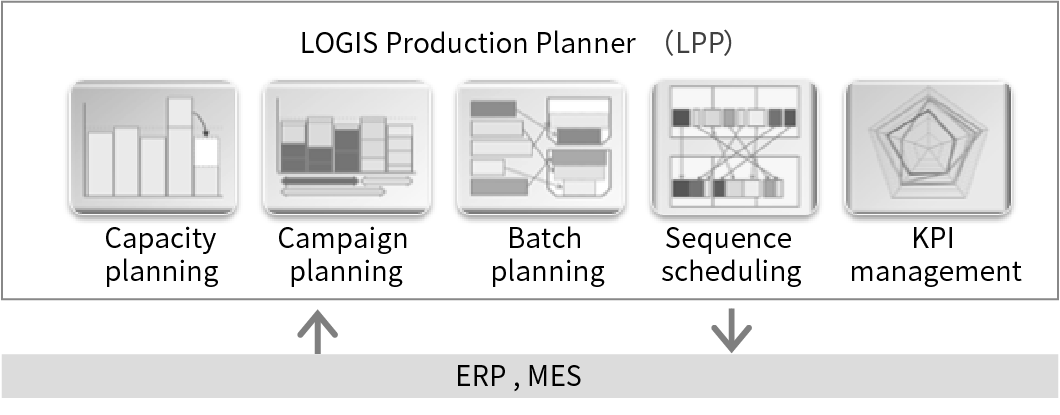

LPP is a next-generation planning solution that can create production plans (Capacity Load Plan, Opportunity Plan, Batch Plan, Sequence Plan) that are totally optimized in consideration of equipment constraints and manufacturing rules, while linking information with ERP and MES, as well as production plans to achieve KPI targets.

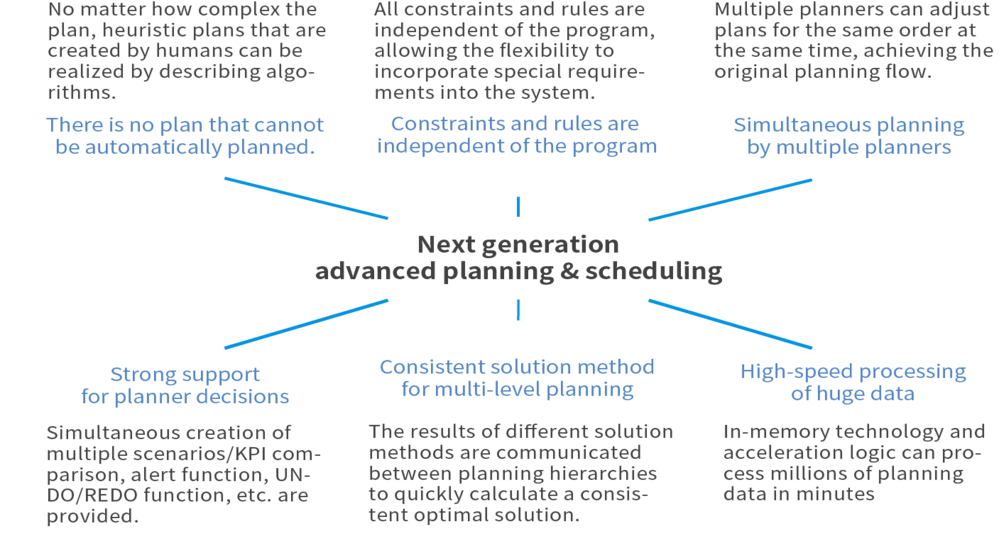

In addition to the package standard functions, it is possible to add or change your own constraints, rules, and algorithms. Therefore, the system can grow by responding to new requirements that emerge as the system continues to operate. In other words, it is said to be able to make planners' dreams come true.

Features - Compatible with Next Generation Planning (APS)

Benefits

- Improving customer responsiveness Since you can quickly formulate a workable production plan and provide delivery dates, you can aim to improve the accuracy of delivery date responses and the rate of delivery compliance.

- Improving production efficiency Since it is possible to create an integrated integrated plan that links the capacity load plan for the entire process and the sequence plan within the process, it is possible to aim for a plan that maximizes the operating rate by eliminating overcapacity and waiting.

- Shortening manufacturing lead time By adopting variable lead times that match the actual conditions at the manufacturing site, manufacturing lead times can be shortened, and in-process inventory between processes can also be reduced.

- Reduced inventory levels The ability to achieve consistent planning with synchronization of overall optimization reduces the level of in-process inventory between processes and product inventory in logistics, as well as inventory management costs.

- Speeding up the PDCA cycle (IoT linkage) The planning cycle can be detailed down to the daily, hourly, or minute level, and even plan at the time of occurrence in conjunction with IoT, allowing you to quickly respond to changes.

- Improved responsiveness to new requirements and security protection Constraints, rules, and unique algorithms can be easily set as data, independent of the program, allowing customers to respond to new requirements themselves. Also, because it is data, there is no need to worry about important confidential specifications being passed on to construction partners.

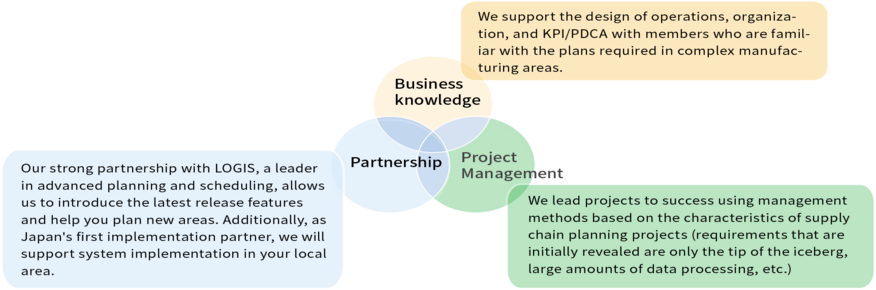

B-EN-G implementation support

Leveraging the planning system implementation methodologies cultivated in industries that require complex planning as well as the large-scale project implementation methodologies cultivated through ERP implementation, together with LOGIS, we provide integrated business and system support for new next-generation planning initiatives, from business conception to operation.