Manufacturing Performance ManagementSAP MII

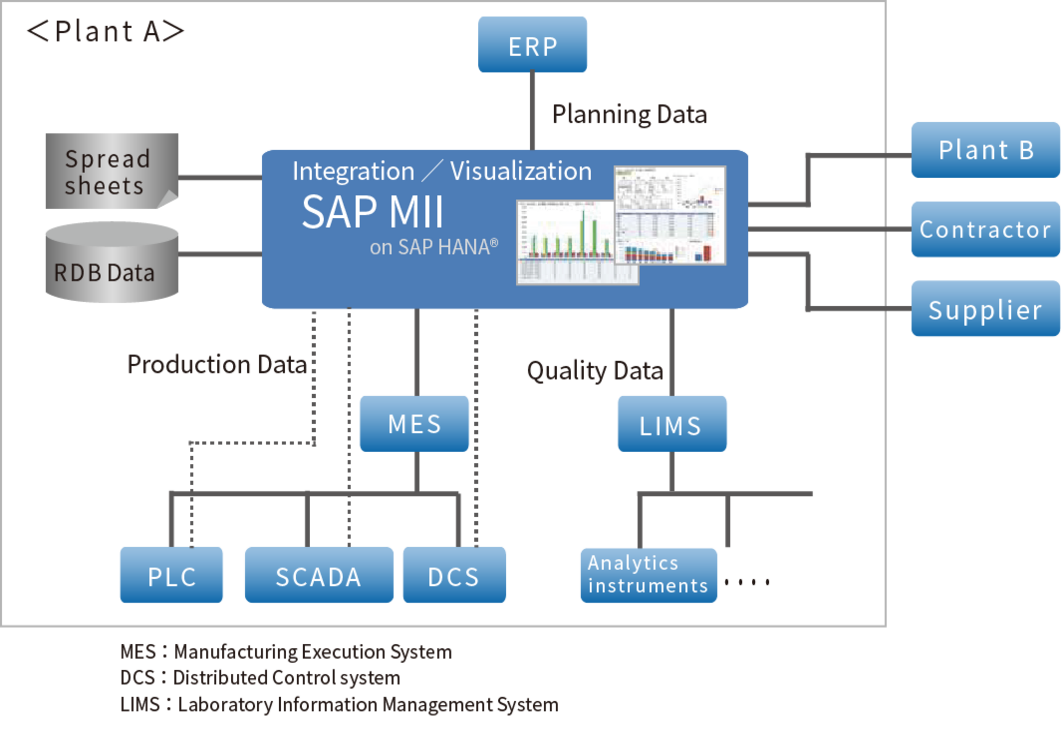

SAP® Manufacturing Integration and Intelligence (SAP MII) is a solution that integrates and displays various data related to planning, manufacturing, and quality in an easy-to-understand manner in order to achieve plan compliance, stable operations, and risk detection. It enables visualization of not only single plant operations, but also multiple plants.

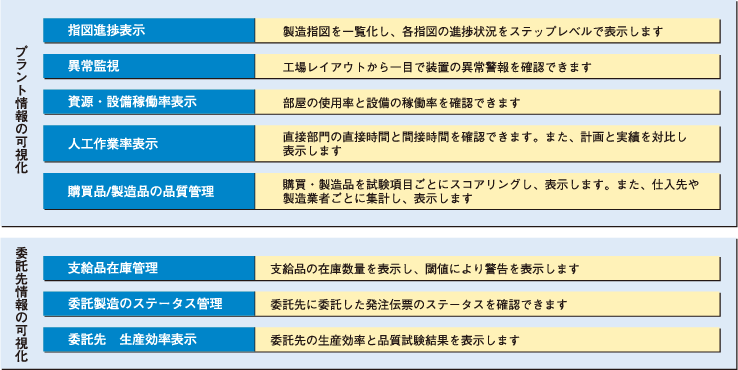

Area of Information Visualization / What you see

Equipped with various connectors, it collects data from ERP, manufacturing management and control systems such as MES※, SCADA, and DCS※, and quality management systems such as LIMS※, to quickly integrate data and visualize the entire factory. The integrated data can be displayed on various SPC charts※, including multivariate analysis. In addition, visualization is possible not only for single factory operations, but also across multiple factories, including the company's own, contractors, and suppliers.

Example of Visualization Using SAP MII

- Manufacturing visibility

-

- Production progress (progress of individual manufacturing orders)

- Equipment operating status, utilization rate, downtime

- Yield standards and performance

- Inventory consumption, volume status, difference from schedule

- Trend analysis using SPC charts

- Visualization of factory operations

-

- Process utilization rate

- Analysis of employee working time and activities (direct and indirect time)

- Visualization of multiple factory operations including subcontractors and suppliers

-

- Inventory management, production progress

- Quality control (test progress, results)

Features of B-EN-G’s Real-time Plant Dashboard

- See the "Now"

-

Real-time information can be collected across multiple plants and companies

- Comparison of plans and performance results

- Helps to forecast manufacturing and personnel tasks for short-term periods (weeks/months)

- Seamlessly aggregate information

-

A wide variety of interfaces are available for data collection at various levels:

- Various databases for systems inside and outside the company (Oracle, MS SQL server)

- In-factory systems (MES, SCADA, production equipment)

- Daily reports managed in Excel spreadsheets

Information gathered from a wealth of data sources can be used as a basis for decision-making and analysis.

- Achieve "0" complexity through single sign-on

- Data managed in each local system is aggregated and necessary information is provided on a single portal screen.

Example of Real-time Plant Dashboard Display

Download Document

Download the "SAP MII" leaflet.

- Manufacturing Performance Management Solution “SAP MII”