It will be three years in October since Business Engineering America, Inc., the fifth overseas subsidiary of Business Engineering Corporation (B-EN-G),wasestablished in Chicago, USA. The company is focusing on selling IoT solutions for the manufacturing industry, but when it first set up shop there, it was unable to adapt to the cultural differences between Japan and the US and found itself at a loss in its sales activities. How did they overcome this challenge? We askedHiroshi Tateoka, president of B-EN-G America, and Jonathan Brandt, a sales representative who has experience as a teacher in Japan, to look back on the past three years.

America never says "NO"!?

"This is the product I've been waiting for" "Amazing!"

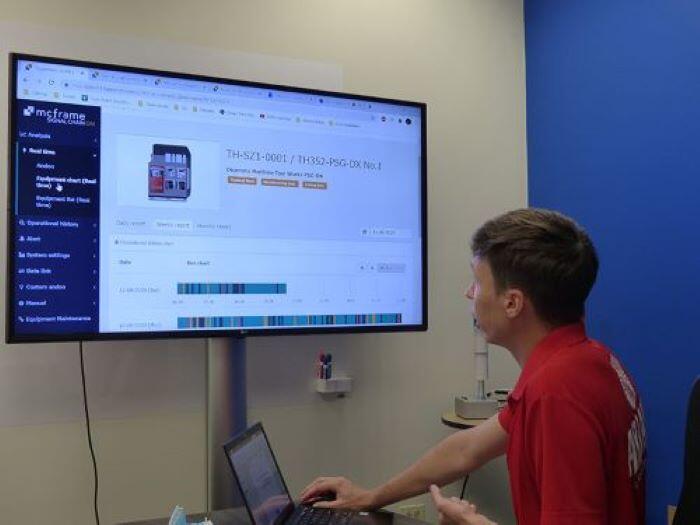

This happened at a manufacturing trade show held in Texas in 2017, shortly after B-EN-G America was founded. When Jonathan explained to the participants about mcframe SIGNAL CHAIN, one of B-EN-G's IoT solutions that can record data on the operating status of manufacturing equipment, they erupted in praise.

Jonathan, who had just joined the company, was on his first day at work at this exhibition. He learned Japanese due to his father, who worked for a Japanese company, and is a Japan lover who says he loves Japanese food "except for natto and shishamo fish." B-EN-G America was his first job in the United States. After graduating from university, he left his job as an English teacher in Saga Prefecture, where he had worked for six years, and joined the company immediately after returning to Japan with his Japanese wife.

Jonathan, when he was an English teacher, at a ryokan in Kurokawa Onsen (Minamioguni Town, Kumamoto Prefecture) during a trip.

Although Tateoka only gave a brief lecture on the product, the booth was a huge success, with "skillful sales talk, just like a veteran employee" (Tateoka). Both Tateoka and Jonathan had no doubt that they would be able to attract new customers.

Jonathan carefully explains things to visitors using the speaking skills he honed during his time as a teacher.

But it was a tough road from there. The attendees he had praised at the exhibition didn't answer his phone calls, and he didn't get a response when he sent them emails. "Americans can sometimes go overboard in an attempt to please others. For example, at a restaurant, I've even been praised by the waiter for ordering a hamburger steak, calling it 'perfect,'" Jonathan says with a wry smile.

Tateoka, who graduated from a state university in the United States, also points out the unexpected gap, saying, "When I studied abroad, there was a stereotype of Japanese people being vague and Americans saying clearly yes or no, but these days, Americans tend to be more perceptive of the atmosphere than Japanese people in some ways. They're like people from Kyoto, who say everything in a sugar coat so as not to offend anyone."

Personal profits over company profits

There are other cases where the cultural differences between Japan and the U.S. have caused problems. In the U.S., where people change jobs frequently, it is not uncommon for people in charge to suddenly change. There have been many cases where projects have been delayed or canceled due to insufficient handover.

"The United States is an individualistic country, for better or worse," says Tateoka. Since it is common for people to change jobs repeatedly in search of better treatment or to improve their skills, the key factor while employed is how to enrich one's work history.

"Being proficient in software that is used globally can be an advantage when changing jobs, but the same cannot be said for Japanese software, so it is necessary to clarify what benefits there are to adopting the software. It is necessary to convince the person in charge that adopting the software will have a concrete effect on the factory and will be a positive addition to one's career," says Tateoka.

Is face-to-face better than email?

As for the differences between Japanese and Americans in business, let's take email as an example.

"Japanese people tend to be diligent, so you'll get a quick response when you send a message. However, Americans have preferences when it comes to communication methods. Many people have no problem using the phone, but many people tend to neglect email. It's difficult right now because of the COVID-19 pandemic, but it's important to make sure to arrange your next appointment in a face-to-face setting, such as an exhibition." (Jonathan)

The spread of the new coronavirus has led to more opportunities for online product explanations in the United States.

Another American trait is not being shy about offering free trials of software. Jonathan says that while Japanese people would try only the functions they really need, "Americans want to try everything."

Even when introducing IoT solutions, there are many cases where people try new fields but end up failing because they want too many different functions from the beginning. "I try to teach the Japanese way of first narrowing down the scope of implementation and then gradually expanding it while assessing the effects," he said.

Thanks to their steady sales activities, the number of companies that have introduced B-EN-G's mcframe series has reached about 50 in the United States and Mexico (as of August 2020). In some cases, companies that had switched to other companies during initial negotiations came to B-EN-G America for help, saying, "We tried to collect all kinds of data from within the factory, but failed."

"The companies that have introduced B-EN-G's IoT solutions have been able to operate them smoothly. We've also heard requests to expand the scope of application to more facilities, so it seems that the direction we've been heading in was not wrong," says Jonathan, who is feeling the results.

The B-EN-G America booth at Hannover Messe Mexico. Interest in IoT is high in the country as well.

The reason behind B-EN-G's decision to establish a local subsidiary in the U.S. is that it wants to compete on the world stage as a Japanese software vendor. We spoke to Tateoka about B-EN-G's key IoT solutions and the current state of manufacturing in the U.S.

The long-cherished wish of Japanese software

--It's been almost three years since B-EN-G America was founded. Could you tell us about how it was originally established?

"It all started when IoT itself became a global trend. B-EN-G has been developing IoT solution-related products for the manufacturing industry since early on. However, in the world of software, basically everything comes from the US. In any case, if you can't make your presence felt in the US market, you will soon be selected out. Mobile phones are a good example, as they became "Galapagos-like" because they stuck to the Japanese market. The Japanese IT industry is constantly being pushed back by the US, but we thought that we had a chance of success with IoT solutions for the manufacturing industry, an area in which Japan excels."

"Another aspect is President Trump's 'America First' policy. In the United States, the effects of globalization that began around 2000 led to the relocation of factories overseas, causing the hollowing out of the manufacturing industry. However, there is now an accelerating movement to bring manufacturing back to the United States. I believe that the groundwork has been laid for IoT to become a major part of our business."

--Has the U.S. manufacturing industry lost its strength compared to before?

"Over the past 20 years or so, a considerable amount of technology and human resources have left the manufacturing industry. Japan and Germany have established strong positions as manufacturing nations, followed closely by China, and the United States is one step behind. Our rival products are also made by German and Canadian companies, and there are not many American companies. It is difficult to create software for manufacturing sites without the accumulation of manufacturing knowledge."

IoT is a factory's "household account book"

--Please tell us about the features of B-EN-G's IoT solutions.

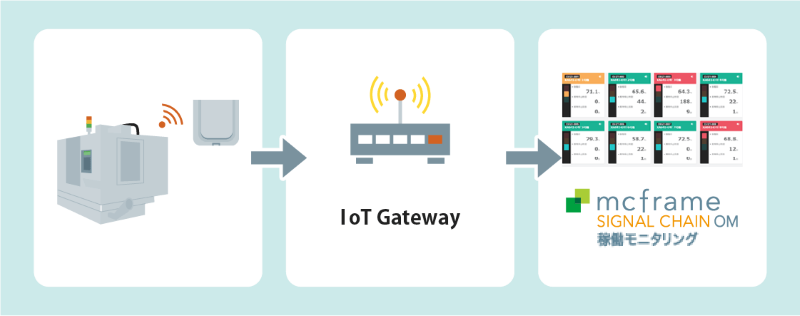

"Before the advent of IoT, even if a factory's on-site manager wanted to know the operating status, they couldn't grasp it in real time. Also, even if they just said they were going to collect data from PLCs, there were actually many issues, such as whether it was operation data or sensing data, in what format and how often it was sent, whether the data was correct in the first place, and what the IT vendor's equipment for verifying the connection would be."

"However, with our mcframe SIGNAL CHAIN, simply attaching an IoT device to the signal lights in the factory makes it possible to wirelessly transmit information such as what color the light is currently flashing. In addition, the factory's operating status is displayed on a dashboard, making it easy to understand at a glance."

"It may be easier to understand if you compare it to a household account book. Even if you say, 'Our expenses have increased recently, so let's cut them down,' it's no use if you don't know the exact amount of the expenditure. However, if you can see that an expenditure that was previously 50,000 yen has increased by 30,000 yen to 80,000 yen, it becomes easier to consider improvement measures. A factory is the same as a household account book. It is important to use IoT to 'visualize' the operating status of the factory."

"In addition, with mcframe RAKU-PAD (sold in the US as mcframe R-PAD), daily manufacturing reports and slips that were previously handwritten on paper can now be replaced with a tablet device (iPad). Previously, it was not uncommon for the data to have to be reconstituted in Excel later, and it would take a month for managers to be able to view the results, but by entering the data into R-PAD, the data can be checked immediately, and if there is a problem, corrective measures can be taken immediately."

Kaizen knowledge applied to IoT

--What are the strengths of B-EN-G's IoT solutions?

"Our solutions are packed with the knowledge of Japan's manufacturing industry, which has steadily continued to implement 'kaizen' (improvement) practices. Collecting and analyzing data may look easy, but it is actually very difficult. Our solutions are packaged and can be used immediately, which is our greatest strength. We can also make any necessary settings or changes in-house."

--What should we pay attention to when introducing IoT solutions?

"There are many things to consider, but the first thing to consider is human resource development. It is essential to be able to analyze and utilize the large amounts of data collected by IoT, but the reality is that there are very few people who can do this. That said, we cannot recommend leaving it all up to IT vendors. After all, only your own staff has knowledge of your own company's field, and if you leave it all up to an outside company, you risk ending up with a large-scale system that is unnecessary and unusable."

"U.S. factories that have introduced our solutions have said things like, 'Previously we operated based solely on experience, but now our workplaces are able to hold discussions based on data.' We hope that our solutions will help the Japanese kaizen culture take root in U.S. factories and improve their manufacturing capabilities."

Members of B-EN-G America. From left: Jonathan, Tateoka, and Mitchell (IoT technology specialist)

(Text: Kyodo News Digital)

*This interview is current as of August 2020.