In the early 2000s, manufacturing companies from all over the world flocked to China. We interviewed Sun Qiang, the current general manager, who was there at the time, about B-EN-G Shanghai, the company's first overseas base, and the newly established development and maintenance center in Shenyang.

"I was attracted by the very open atmosphere," Son recalls of his impression when he started working at B-EN-G's headquarters (Chiyoda-ku, Tokyo) in 2001. After graduating from an engineering university in Shanghai, he worked for a construction equipment manufacturer in Sichuan Province, but then he decided to make a fresh start and move to Japan to study engineering at Tokyo University of Agriculture and Technology. At that time, China was emerging as the "world's factory," but the concepts of "production management" and "cost management" were still weak.

In 2004, a major client to whom B-EN-G's headquarters had introduced an ERP system established a factory in China. B-EN-G also established a representative office in Shanghai to provide support on the ground. Wanting to contribute to the business in his home country, Son took a training course on "mcframe CS" (currently production and cost management for overseas bases) at the headquarters, with the assumption that he would return to China. After learning about the system's functions and the types of work required at the user's manufacturing site, he created a Chinese version of the system in 2005.

Son was posted to China the following year, and set a goal of "selling one in three years," and began market research. SAP, Oracle, and other Chinese-developed ERP systems had already begun sales in China, and mcframe CS was a complete "latecomer." However, Son said, "I thought that a system packed with Japanese manufacturing know-how would definitely be useful."

A rocky start and local incorporation

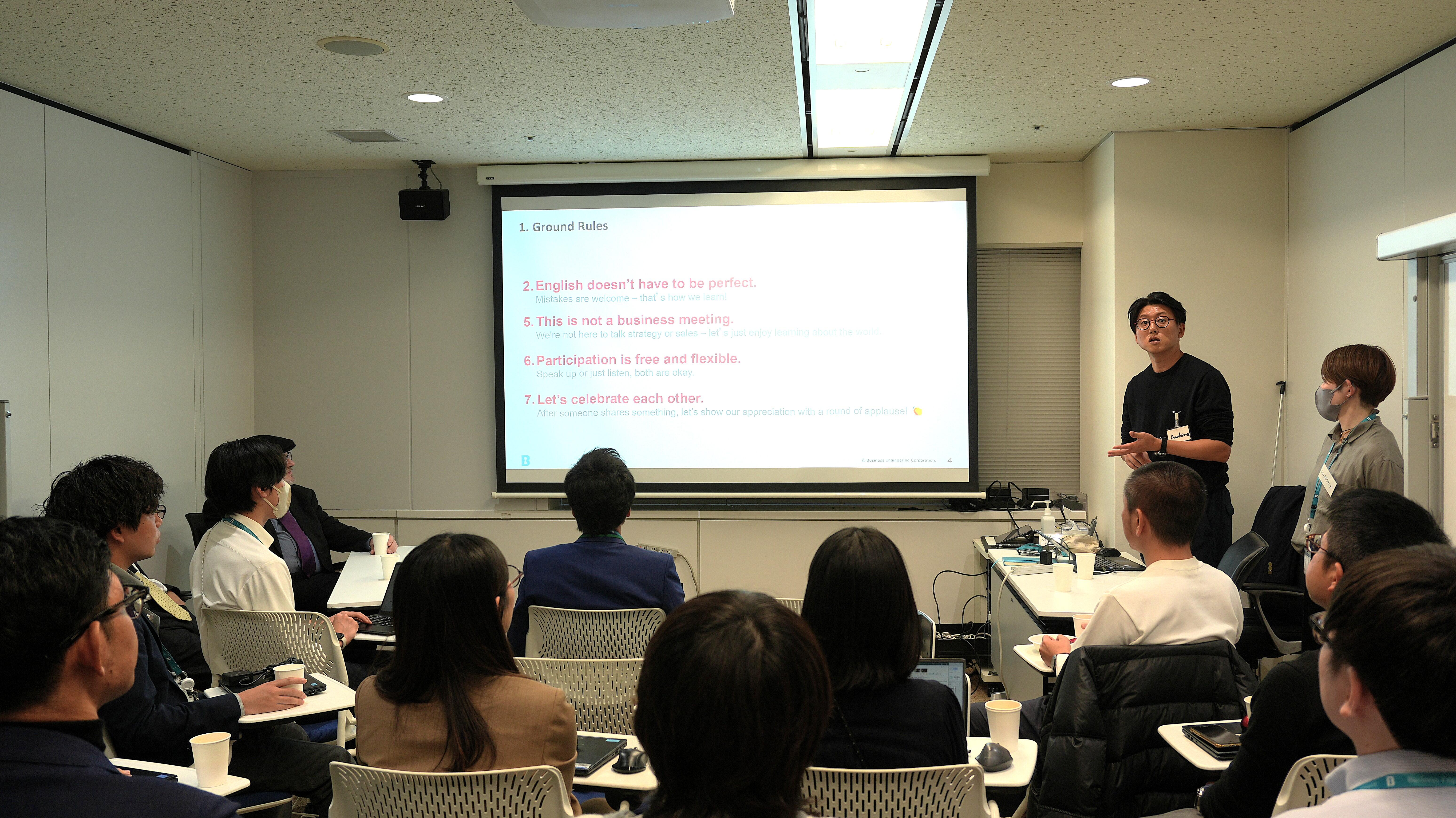

Grandson and the B-EN-G Shanghai members at the time

Grandson and the B-EN-G Shanghai members at the time

Although he pushed himself hard in sales activities to achieve his goal, the reality was harsh. He reached the final stage of contract negotiations with several companies, but at the very last moment, he repeatedly failed to secure orders. "It was rewarding and fun, but it was hard not to see results," says Son. At one sales call, he was told, "We trust you. We understand that your system is good. But if you're gone, what will happen to us?" This was an expression of concern about the system. At the time, Son was the only person in the Shanghai representative office.

So in 2007, they started to seriously hire and train developers, strengthening their organization. This change in direction paid off, and they won their first project. It was December 2008, just as Son's goal of three years was coming to an end. The three Chinese employees who were in charge of the implementation at that time are still working at B-EN-G Shanghai today.

In 2010, the representative office was converted into a local corporation in order to strengthen sales of mcframe CS in China. The number of employees increased to 10, and active sales were conducted, mainly in coastal areas. Users spread from Shenyang in the north to Hong Kong in the south. Sales doubled in about 10 years, and the number of mcframe CS contracts exceeded 40 companies.

In 2017, the company established an IoT department to meet the needs for automation and smart manufacturing in line with the global trend of Industry 4.0 and the Chinese government's "Made in China 2025." An increasing number of Chinese manufacturers are feeling a vague sense of anxiety that they will be left behind if they do not work on automation and informatization. However, many companies do not have a foundation for data integration within their factories for automation, and Son believes that "in order to achieve 4.0, we first need a solution to bring it to about 2.5." In fact, many of B-EN-G's IoT solutions, such as "mcframe SIGNAL CHAIN" and "mcframe MOTION," provide an "entrance" to IoT. (Details of IoT products will be provided in an article to be published at a later date.)

Development and maintenance center established in Shenyang

Shenyang, where the mcframe CS development and maintenance center is located

Shenyang, where the mcframe CS development and maintenance center is located

A new initiative within the B-EN-G group is the mcframe CS development and maintenance center that was established in Shenyang in 2016 together with a partner company. The rising labor costs of development personnel in Shanghai are one factor behind the decision, but Shenyang was chosen because of the abundance of excellent Japanese-speaking personnel. The main work is the maintenance and improvement of mcframe CS and customer support. Currently, mcframe mainly sells the "mcframe 7" series, but there are many users who have been using the CS series for many years, and the center is solely responsible for supporting them.

Since the company was established, Son has made it a priority to share the awareness that everyone is "part of the same team," not just "offshore base." Once you start thinking of it as an offshore base, you tend to worry about writing even something as simple as a specification or design document, thinking, "I have to write it properly." This is not a bad thing in itself, but being too careful can lead to unnecessary processes and lost time. Son spent about two years meticulously developing the development management system and rules. He created manuals on how to write basic and detailed design documents, as well as testing procedures and precautions. By clarifying the rules, work efficiency improved and the quality of projects also improved. Now, the company is also contracted by Japanese partner companies for maintenance work.

Bringing Chinese solutions to the world

Currently, B-EN-G Shanghai employs around 30 Chinese employees. Many of them are systems engineers and consultants who can speak Japanese and understand production management. Son guarantees that they can answer any questions about manufacturing-related systems, whether that be production management, cost management, IoT, or products from other companies. B-EN-G Shanghai says that its strength lies in the fact that it has such excellent human resources and a backup system in place at its headquarters in Japan in times of trouble. In fluent Japanese, Son described the support of its employees and headquarters as a "treasure."

Furthermore, Son has set himself a new goal for the next 10 years. He wants to sell not only the licenses for products developed by the head office, but also solutions developed at B-EN-G Shanghai in China in Japan and other overseas bases. "Just as cashless technology quickly spread in China, the time will come when systems developed in China will be accepted in Japan and around the world in the manufacturing industry. I want B-EN-G Shanghai to be the driving force behind this," says Son. Having achieved his goals when he was assigned to this post, this man of his word is now aiming to be at the forefront of information systems.

(Reporting cooperation: NNA / Supervision: Kyodo News Digital)

*This interview is current as of September 2019.

Click here to see the Sekai no Chikara