News

JAM implements a function to identify the cause of abnormalities using high-speed cameras in its crimping machines

- Visualizing operations that cannot be followed visually with video and data, contributing to speeding up the investigation of abnormalities and minimizing production losses -

The first double-end crimping/single-end crimping and insertion machine will be demonstrated at Internepcon

Japan Automatic Machine Co., Ltd.

Business Engineering Corporation

Japan Automatic Machine Co., Ltd. (Head office: Ota-ku, Tokyo; President and CEO: Masafumi Mizuno; hereinafter referred to as JAM) and Business Engineering Corporation (Chiyoda-ku, Tokyo; President and CEO: Masakazu Haneda; hereinafter referred to as "B-EN-G") announce that they will begin offering a double-end crimping/single-end crimping and insertion machine equipped with an operation monitoring system with an abnormality recording function from the end of March 2026. In addition, prior to this, JAM will demonstrate this product at the 40th INTERNEPCON JAPAN, an electronics manufacturing and packaging technology exhibition to be held at Tokyo Big Sight for three days from Wednesday, January 21st to Friday, January 23rd, 2026.

■40th Internepcon Japan Exhibition Overview

Date and time: Wednesday, January 21, 2026 - Friday, January 23, 2026

Venue: Tokyo Big Sight, East Hall 5, Booth No.: E13-40

■Background and Issues

At wire harness processing sites that use automatic crimping machines, identifying the cause of crimping abnormalities is a challenge. Conventional network cameras can capture an overall image of the machine, but they cannot accurately capture the high-speed operation of the crimping machine, so the only way to determine the cause of crimping abnormalities is to infer it from past events and on-site experience.

Meanwhile, with the advancement of digitalization, there is an urgent need to utilize operational data for predictive maintenance and production efficiency improvement. However, even to address this issue, operational data alone is not enough to fully understand what is actually happening in the machine, and investigation of the cause after detecting an abnormality still relies on on-site experience.

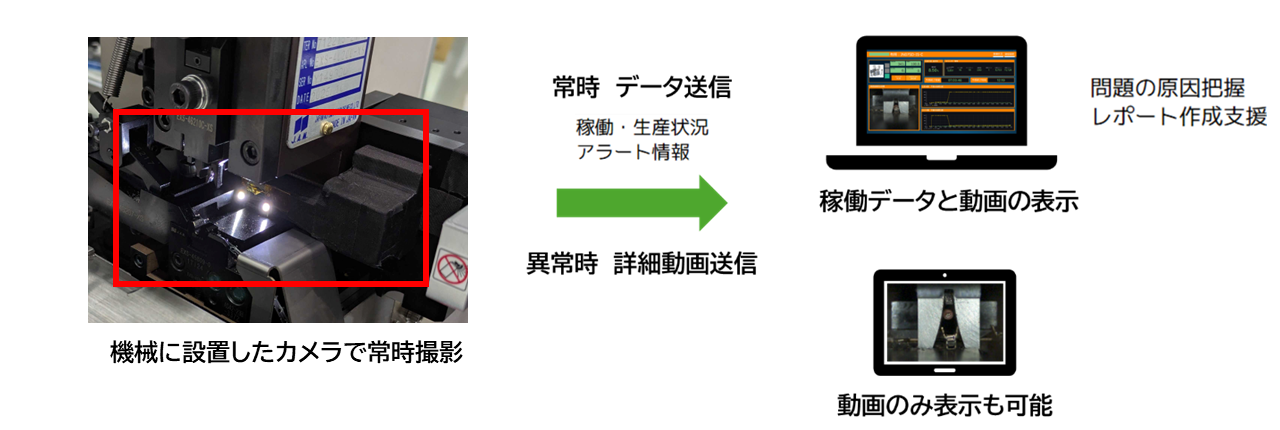

To solve this problem, JAM and B-EN-G collaborated to develop an operation monitoring system with an abnormality recording function that combines "video recorded in millisecond units" and "operational data" when an abnormality occurs by combining a high-speed camera with the operation monitoring system "mcframe SIGNAL CHAIN."

■ Overview

JAM's double-end crimping/single-end crimping and insertion machines are equipped with a high-speed camera developed by the company, and when an abnormality is detected, only the necessary parts of the video data that is constantly recorded are stored on the server. This is then synchronized with the operation data sent from the machine and can be displayed and analyzed on "mcframe SIGNAL CHAIN" via a web browser on a PC or tablet.

By linking and checking the operation data and video, the cause of crimping abnormalities can be identified quickly and accurately.

■Benefits of the abnormality recording function

By playing back videos recorded during abnormal situations in slow motion and analyzing them together with operational data, the following benefits can be obtained:

- Speeding up response to crimping abnormalities: By visualizing high-speed phenomena that cannot be seen with the naked eye, even non-experts can accurately grasp the phenomenon, investigate the cause, and take appropriate action, reducing production downtime.

- Preventing recurrence of problems: Recorded videos and data are saved for a certain period of time, allowing for retroactive investigation into causes and the development of measures to prevent recurrence of past problems.

Screen example

JAM will incorporate these functions into its fully automatic terminal crimping machines and provide them to customers, thereby accumulating a variety of operational data that will lead to improvements in maintenance and other services.In addition, by utilizing this data in future product development, JAM will provide long-term value.

■About Japan Automatic Machine Co., Ltd.

Japan Automatic Machine Co., Ltd. is a company with precision processing technology that has been accumulated since its founding in 1932.

With the business concept of "MACHINES & CONNECTORS," we are a cutting-edge technology development company for electronic components, crimping machines, and precision machinery, with five production bases in Japan and three overseas in China, Thailand, and India, and sales and service bases in seven in Japan and overseas in China, Singapore, Malaysia, Thailand, India, Europe, and the U.S. We have a global presence, with a vision of becoming our customers' best partner through "manufacturing" and "value creation" that exceeds expectations, and we are constantly challenging ourselves with our integrated system of development, production, sales, and maintenance, and our comprehensive strength that combines machine and connector technologies.

For details about Japan Automatic Machine Co., Ltd. https://jam-net.co.jp/company/outline/ Please see.

■About Business Engineering Corporation

Business Engineering uses IT to support the digital transformation of customers, primarily in the manufacturing industry. We have a strong track record in consulting and support services ranging from IT planning to system construction, implementation, and operation, as well as the sale and implementation of our proprietary package software, "mcframe." We also utilize data accumulated in enterprise resource planning (ERP), supply chain management (SCM), IoT, and other systems to help customers improve their systems and implement kaizen (improvement) activities. With five overseas subsidiaries in China (Shanghai), Thailand (Bangkok), Singapore, Indonesia (Jakarta), and the United States (Chicago), we provide products and services to companies expanding overseas, working closely with them both in Japan and locally, to help resolve their management challenges.

For more information about Business Engineering Corporation https://www.b-en-g.co.jp/ Please see.

For more information about Business Engineering's "mcframe SIGNAL CHAIN," please see

https://www.mcframe.com/product/signalchain Please see.

Note: All product names and names mentioned in this release are the trademarks or registered trademarks of their respective companies.

Business Engineering Corporation

Public Relations Group, Corporate Administration & Planning Division

TEL: 03-3510-1619

For inquiries, please contact us here.

Japan Automatic Machine Co., Ltd.

Contact form:

https://jam-net.co.jp/jamform/