Challenges

Realization of a strategic system that enables real-time management from the management, production, and cost perspectives

Implemented Products/Solutions

SAP R/3, B-EN-G individual order production model B-EN-Gm

Project Background

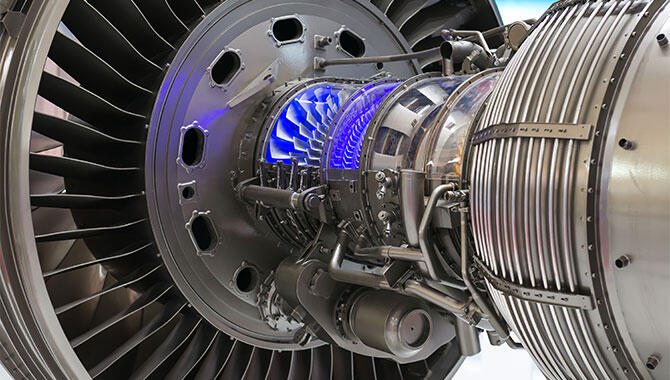

The major domestic machinery manufacturer in this case is a representative company in Japan that operates a wide range of businesses, including transportation equipment and industrial machinery.

The important theme was to realize real-time performance in each aspect of management, production, and cost for the entire production process within the factory. In other words, there was a need to promote integrated and centralized management of information, streamline operations, and achieve accurate and speedy decision-making as a result.

Therefore, we launched a business reform project and set very high goals in terms of improving productivity, reducing inventory, and shortening lead times. As a way to achieve this, they decided to introduce ERP, and then proceeded with a comparative study of each product.

Reasons for Selecting B-EN-G as an Implementation Partner

In order to achieve our goals, we needed to reform our business processes from the ground up, and at the same time proceeding with BPR (Business Process Re-Engineering), we determined that we needed an ERP to support the new business, and we selected Individual Orders. This is an implementation of SAP R/3 using the production model "B-EN-Gm".

B-EN-G was selected as the implementation partner for SAP R/3 because of "B-EN-Gm," a model prepared for SAP R/3 to function in response to individual order production, semi-made-to-order, and semi-make-to-stock production. B-EN-G also had a track record of implementing SAP R/3 for over 100 companies.

Implementation Results

As a result of the introduction, a "strategic system that enables real-time management from the perspectives of management, production, and cost" was established, and the following effects were achieved.

In this project, by using "B-EN-Gm" as a reference model at the time of implementation, the workload during the planning phase was greatly reduced, and sufficient study could be conducted during that period, resulting in a significant reduction in the number of forms and shortening the project period by minimizing additional development.

In addition, since users have had opportunities to come into contact with the system from an early stage based on "B-EN-Gm," BPR/ERP has become more widespread among users, leading to increased user awareness.

*Please note that organization names, positions, numerical data, etc. in the article are based on the time of the interview and may have changed by current viewing.

Related Solutions

Relevant information and case studies based on solutions presented above.

Related Case Studies

Nippon Cargo Airlines Co., Ltd.

Aiming to Shift to High-Value-Added Businesses: A Case Study of Accounting System Restructuring with RISE with SAP

Logistics

ERP

SAP

Idorsia Pharmaceuticals Japan Ltd.

Compatible with Global Requirements: Case Study of a Project to Build a Sales Management System Compatible with JD-NET

Medicine

ERP

Pharmaceutical & Medical Device Industries

SAP

GE Healthecare Pharma Limited

Promoting Understanding among Global IT Teams: JD-NET-compliant Enterprise Resource Planning System Implementation Project Case Study

Medicine

ERP

Pharmaceutical & Medical Device Industries

SAP