News

B-EN-G utilizes natural language analysis technology to

Supporting the sophistication of Suzuyo's safety management process

Build a data mining system that suggests "risk level" and "effective countermeasures"

Business Engineering Corporation

Business Engineering Corporation (Chiyoda-ku, Tokyo; CEO: Masakazu Haneda; hereinafter referred to as "B-EN-G") is pleased to announce that it has built a data mining system that utilizes natural language analysis technology to enhance the safety management process of Suzuyo Co., Ltd. (Head office: Shizuoka City; CEO: Kenichiro Suzuki; hereinafter referred to as "Suzuyo"), a major comprehensive logistics company, and has begun supporting the company in establishing the system's operation.

Suzuyo introduced B-EN-G's iPad software "mcframe RAKU-PAD" in 2018, digitizing "near misses," "accident reports," "risk assessments," and "patrol activities," which had previously been done on paper. In the course of using mcframe RAKU-PAD, reports from bases scattered across the country were accumulated as data, and the numbers made it clear that there was a disparity in the achievement of "safety" and "quality" goals for each logistics center. It was also discovered that there were logistics centers where similar near misses and accidents were repeatedly reported.

Therefore, we requested B-EN-G to analyze the data, with the goal of preventing accidents before they happen by performing natural language analysis on the accumulated data, thereby eliminating the variation in awareness and countermeasures among managers. As a result, we found that natural language analysis technology is useful for enhancing the safety quality management process by exploring the risk of accidents, determining the effectiveness of countermeasures, and conducting PoC. Based on these results, we started building a data mining system.

■ What can be achieved with the "data mining system" we have built

This data mining system achieves the following:

- You can find documents with similar content, check for recurring events, and suggest preventive measures.

- You can find examples of effective countermeasures and deploy them to other distribution centers.

- The degree of risk can be suggested from keywords that frequently appear in the “contents” and “countermeasures” of the form.

- You can understand the number and percentage of near misses and accidents by experience and chronologically.

By utilizing data mining systems in daily safety and quality control activities, it becomes possible to make quick and accurate decisions based on data (facts) rather than measures that emphasize empirical rules. Specifically, similar documents can be immediately identified from a large number of past documents, reducing the workload when formulating new countermeasures, and providing guidance and education based on decisions based on numerical values rather than experience. You will be able to.

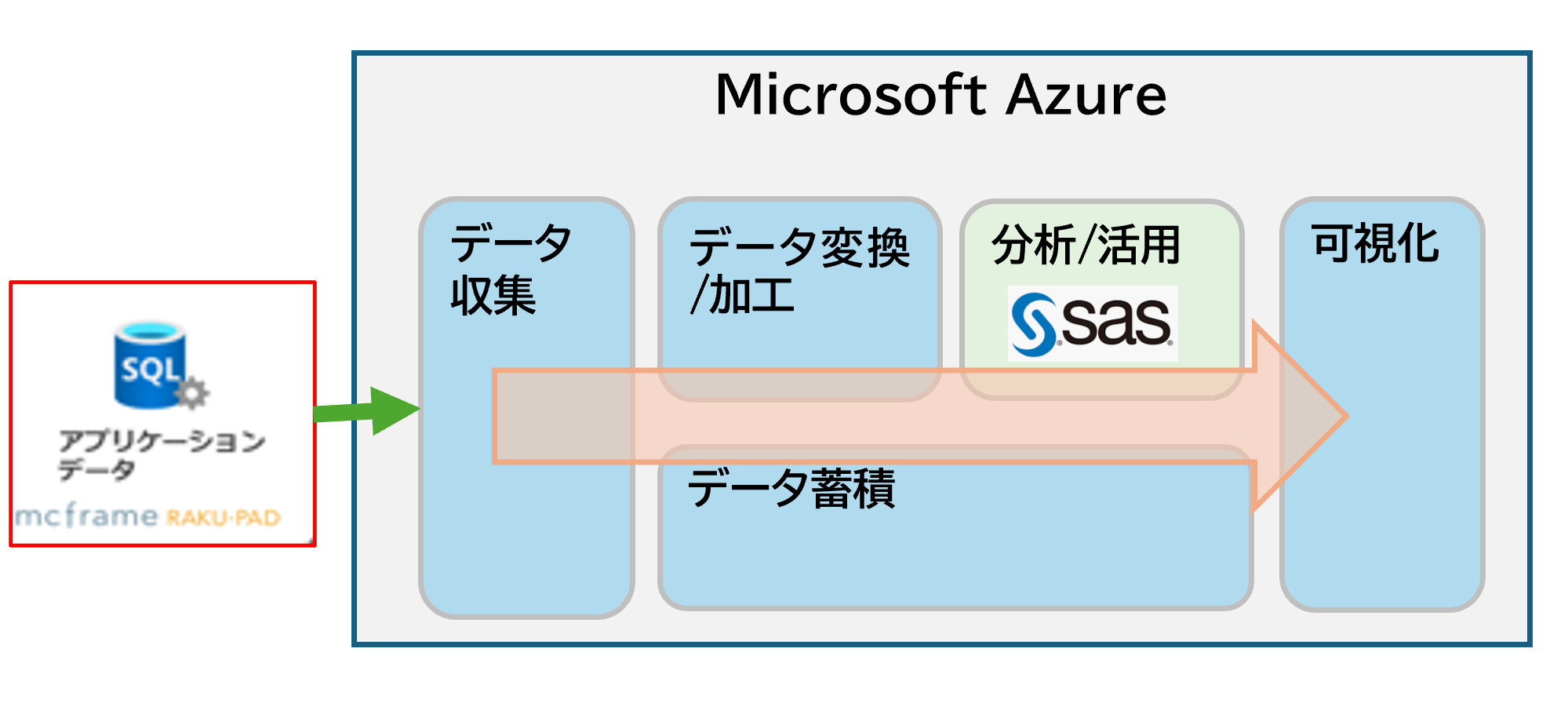

The data mining system uses Microsoft Azure as the data analysis platform, SAS Viya as the analysis tool, and Power BI as the visualization tool.

■ Suzuyo's future policy

By training staff who can utilize the data mining system we have constructed at our logistics centers and continuously promoting activities to utilize data, we will establish data-driven management as an organization. We also aim to utilize the accumulated data in other areas, such as improving profitability and valuing logistics data (value creation).

B-EN-G will continue to provide a full range of support services to help Suzuyo improve its safety and quality control processes.

■Comment from Mr. Kawai, General Manager of Suzuyo 3PL Business Promotion Office

At our company, we have been using RAKU-PAD for many of our safety and quality activities since 2018. As a result, various safety and quality data has been accumulated, and by analyzing the patterns, causal relationships, and correlations of that data and continuing to obtain suggestions that will lead to preventive activities, we hope to improve safety and quality (preventing accidents and incorrect shipments) and the quality of our safety and quality activities.

One of our business challenges is the realization of safety quality management through data mining. Currently, decisions are made based on information and evidence obtained through safety measures that emphasize rules of thumb and data analysis mainly using Excel work, but since we expect to be able to make decisions more quickly and accurately, we asked B-EN-G to build a system that links the data stored in RAKU-PAD and other data, and uses natural language analysis and machine learning to formulate more accurate measures. We look forward to B-EN-G's continued support in establishing analysis and operation and maintenance using this system.

■About Business Engineering Corporation (B-EN-G)

Since implementing SAP ERP for the first time in Japan in the early 1990s, Business Engineering has been supporting the digital transformation of customers, primarily in the manufacturing industry, through IT. We have a strong track record in consulting and support services ranging from IT planning to system construction, implementation, and operation, as well as the sale and implementation of our in-house developed package software, "mcframe." We also use data accumulated in core business systems (ERP), supply chains (SCM), IoT, etc. to help with system advancement and kaizen activities. We have five overseas subsidiaries in China (Shanghai), Thailand (Bangkok), Singapore, Indonesia (Jakarta), and the United States (Chicago), and have established a strong presence in Japan.

For more information about Business Engineering Corporation https://www.b-en-g.co.jp/ Please see.

■ B-EN-G's efforts in data analysis

For over 20 years, B-EN-G has been providing implementation services for ERP (Enterprise Resource Planning), MES (Manufacturing Execution Management System), LIMS (Quality Inspection Management System), SCM planning systems, and various IoT products. In April 2020, we launched the DcX Business Promotion Department (Data-centric Transformation), a specialized organization that combines accumulated data and various external data, handles data according to purpose, and derives insights using statistics, machine learning, AI, and other methods.

For more information about B-EN-G's DcX support services, please see below.

https://www.b-en-g.co.jp/jp/solution/dm/dcx.html

For information about B-EN-G's general services supporting data-driven management, please see below.

https://info.b-en-g.co.jp/lp-data-chain

About Suzuyo Co., Ltd.

As a comprehensive logistics company, with a diverse network of 140 locations in Japan and over 140 countries around the world, centered around Shimizu Port, we make full use of our strengths in on-site capabilities, problem-solving capabilities, and outstanding expertise to propose logistics strategies that optimize our customers' entire supply chains, as well as the construction and operation of systems.We are also actively working to build "sustainable logistics," providing transportation services that reduce environmental impact.

For more details https://www.suzuyo.co.jp/ Please see.

Note: All product names and names mentioned in this release are the trademarks or registered trademarks of their respective companies.

Business Engineering Corporation

Corporate Administration & Planning Division Public Relations Group

TEL: 03-3510-1619

ContactUs

ビジネスエンジニアリング株式会社

ソリューション事業本部 営業本部

TEL: 03-3510-1622

E-mail: solution-info@b-en-g.co.jp